How to make a warm floor in an apartment or house so that it serves for many years, is durable, reliable and resistant to mechanical damage? Which laminate flooring is better to choose? What do you need to know for this? How to choose a substrate for a warm floor?

Is laminate flooring “warm”?

A material called "warm laminate" does not exist. However, with the development of modern technologies, specially developed varieties of laminate have appeared that perfectly combine with any type of underfloor heating. To understand what type of laminate is needed for a particular type of floor heating, marking on the packaging of the material and the accompanying documentation (instructions) attached to the product will help.

Marking

"Permissive" characters from the manufacturer:

- U-shaped or S-shaped image of the heating element

- arrows pointing vertically upward (rising warm air)

- + 0С - temperature designation (next to the sign, the maximum permissible temperature value, which cannot be exceeded, is usually indicated)

- E1, E0 — material emission class

- H2O - this symbol means that the laminate is compatible with a warm water floor.

The instructions for the laminate indicate the type of floor heating - electric, infrared film or water, for which this material is intended.

You may need it

Marking

"Permissive" characters from the manufacturer:

- U-shaped or S-shaped image of the heating element

- arrows pointing vertically upward (rising warm air)

- + 0С - temperature designation (next to the sign, the maximum permissible temperature value, which cannot be exceeded, is usually indicated)

- E1, E0 — material emission class

- H2O - this symbol means that the laminate is compatible with a warm water floor.

The instructions for the laminate indicate the type of floor heating - electric, infrared film or water, for which this material is intended.

You may need it

Types of underfloor heating under the laminate

Depending on the chosen brand of flooring, the architectural features of the room, the requirements of the project and other important factors, the warm floor is divided into two categories:

In modern conditions, among the builders and owners of private buildings, the most popular are electric heating systems. This is due to the versatility, compactness, affordability of equipment powered by electricity. Such floors are in turn classified into:

- Cable floor heating (a solid cable is laid by a snake on a special grid, the entire structure is filled with concrete, the layer thickness is about 30 mm).

- Infrared (thermal film).

- Matte (thin wires on a nylon mesh in the form of a single mat).

- Amorphous (metal tape).

Caleo platinum

The South Korean infrared heat-insulated floor Caleo Platinum belongs to the category of energy-saving devices of the fifth generation. The film sections are ideal for laying under parquet boards, laminate, linoleum, carpet, etc. The CALEO PLATINUM package includes: a roll of thermal film, PVC insulation, bitumen, clamps, connecting wires, installation instructions. High-tech floor heating with adjustable power.

- Effective space heating.

- Energy saving (compared to cable underfloor heating, electricity consumption is reduced by almost six times).

- High durability (withstands loads from heavy furniture).

- The system works without overheating.

- The base mesh is made of silver-plated materials.

- Warranty service for 15 years.

- Power self-regulation function.

- Easy installation without the use of adhesives.

- Low resistance to burning.

- Dear floor.

Rexva

The self-regulating infrared warm floor of the South Korean company ReXva enters the distribution network in the form of a heating film complete with a temperature regulator, a corrugated tube to protect the remote temperature sensor. The uniqueness of the design lies in the independent automatic reduction of the floor temperature in areas of possible local overheating (for example, carpets, furniture, a discarded pillow and other items that impede heat transfer). In the manufacture of infrared film ReXva uses advanced developments and modern nanotechnology.

- Competent price-quality ratio.

- Decrease in output power by almost 30% in the overheating zone.

- Profitability.

- Helps increase the life of the laminate.

- Durability.

- Tight lamination of surfaces.

- Increased electrical insulation.

- Fireproof properties.

- Water resistant.

- Increased protection against electrical breakdowns.

- Versatility (adapted for various floor coverings, including linoleum, laminate, tile, carpet, parquet, wood, etc.).

- Warranty - 15 years.

- The surface of the floor strongly attracts dust. End of form

Heat plus

The heating equipment Heat Plus floor heating comes from South Korea. The composition of the infrared film includes flexible carbon strips 1 m wide, mutually connected using copper alloy tires. The device emits long-wave infrared rays that are not harmful to the environment and the human body. To heat one square meter to 50 ° C, 40 to 70 watts of power will be required.

- Versatility (the film can be laid not only on the floor, but also mounted on the walls, ceiling, etc.).

- Quick installation, the material is laid without glue, cement screed.

- High quality workmanship, heating efficiency.

- The heat transfer level is 98%.

- Durability.

- Resistance to wear.

- It can be used without a heat regulator.

- The voltage drops in the electric network are not terrible.

- High price.

Monocrystall ENP

Unlike previous models, Monocrystall does not include silver compounds. As a layer between the heating element and the copper busbar, a special carbon paste is used. Graphite strips are soldered into the polymer film, through which current flows. "Monocrystal" is available in widths of 30-60 cm, models are distinguished: solid, linear, perforated.

- Low price.

- Easy installation, easy connection to a standard 220V power supply.

- Ensuring the heating of the film to a temperature of + 50C.

- Universal application (under linoleum, tile, laminate, etc.).

- Warranty - 15 years.

- There are no cons.

Hi heat

The South Korean warm floor Hi Heat film infrared has a relatively low cost against a background of excellent quality. When laying such a system, you do not need to raise the level of flooring, because the thickness of the IR film is very small, not exceeding 0.4 mm. High Hit film is available in two versions: continuous, consisting of strips.

- Economical option.

- Efficiency, softness of heating.

- Operational safety.

- High degree of protection against self-ignition, electrical breakdowns.

- Relatively low power consumption (0.04 kW / square meter).

- Long service life.

- Universality.

- Easy to lay without screed.

- No flaws were noticed.

Thermal Suite two-core cable

Section heating two-core TLOE of the Teplolux brand with a power of 800 W. It includes a heating cable BNO. The separate heating sections at the outlet and inlet have cold ends with connecting and end mounting couplings located on one side, which is very convenient during installation work. Fixing sections of the warm floor is carried out using special mounting tapes.

- Easy layout.

- Convenience of connection to a temperature regulator.

- Power supply on the one hand.

- Comfort heating control.

- Versatility (suitable for laying under a laminate, tile, tile, etc.).

- Wide set: corrugated protective tube for a temperature sensor, heating section, mounting tape, detailed instructions for installing a warm floor, training CD.

- Warranty - 25 years.

- For comfortable heating, you will need to purchase expensive automatic devices with complex settings.

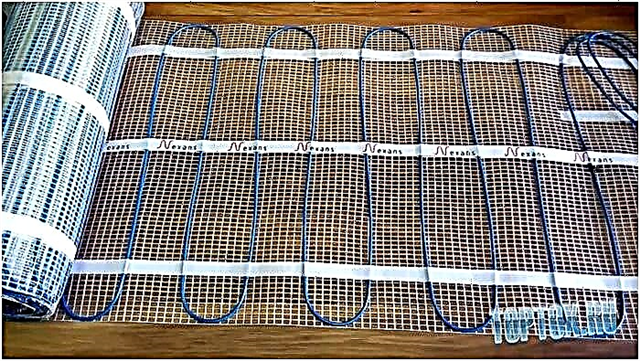

Nexans Millimat

Nexans Millimat floor heating is most often used to heat existing flooring. Thin sheets with a two-wire heating cable are equipped with high-temperature Teflon insulation. The device is a plastic thin fiberglass mesh into which a 2-core cable is woven, placed in an aluminum tube. All this is fixed with an adhesive backing. Each section is equipped with a separate connecting wire made of high quality copper, the wire length is 2.5 meters. Management of the warm floor settings is carried out using the thermostat. Power Millimat 150 - 1800 watts / sq. m

- Convenience of installation, the possibility of laying directly under the coating installed earlier.

- Kits are ready for sale, ready for installation and quick connection.

- The maximum temperature of the external circuit reaches + 65 ° C.

- Long warranty - at least 20 years.

- Repeated use with other floor coverings.

- No flaws were noticed.

Ensto

Heating mats made in Estonia. Ensto floor heating is excellent for rooms with different humidity indicators. This equipment is compatible with floors of any quality: concrete, tile, stone, parquet flooring, laminate Ensto mats are laid on a perfectly even screed. Each package consists of a heating mat, adhesive tape of aluminum, corrugated tube, designed for a temperature sensor.

- Providing a comfortable warm floor.

- Adequate cost.

- Ease of styling.

- Simplicity of operation.

- Durability of use.

- Security.

- Universality of application.

- There are restrictions on the ambient temperature during installation - not lower than +5 degrees.

Veria quickmat

Veria Quickmat twin-core heating element made in Poland. Warm floor sections are designed for installation under floor coverings. Mat power - 150 watts per square meter, thickness - 3 mm. The element includes a 2-core shielded cable with a diameter of 2.5 mm, Teflon insulation (external, internal), designed for high temperatures. The basis for the cable - a self-adhesive mesh made of synthetic materials has conclusions in the form of cold connecting wires. Each section of the warm floor is designed for maximum heating to a working temperature of +120 degrees.

- Convenient easy styling.

- Thin layer.

- High-quality insulation of wires.

- A comfortable stay in a room with such floor heating.

- Reliability of the device.

- Long term of operation.

- Warranty from the manufacturer - 10 years.

- Not seen.

Hemstedt DH / 150

Hemstedt two-core underfloor heating is made in Germany. Hemstedt DH / 150 heating mats with a thickness of 3.5 mm are premium products. The design provides for clutchless connections, insulation of cable cores from high-quality Teflon. Management of programs of a heat-insulated floor is carried out by means of a special heat regulator iReg T8.

- Thin heating element.

- High heating efficiency.

- Possibility of installation without raising the floor level.

- No need for additional thermal insulation.

- Thermostat with touch screen.

- LED backlight, system diagnostics.

- Reliable protection against accidental interference of children.

- Warranty - at least 20 years.

- High price.

What kind of underfloor heating is better to choose

When deciding on the purchase of underfloor heating under the laminate, you need to pay attention to the following factors:

- Technical characteristics and operational properties of laminate boards, to what temperature the floor covering can be heated so as not to cause the emission of harmful substances.

- The presence of a heat regulator.

- How difficult is the selected material?

- What is its effectiveness.

- In what country is this underfloor heating produced.

- The level of operational safety.

- Heat transfer rate.

- The cost of the selected model.

What warm floor under the laminate is best for your apartment, you can understand after comparing the characteristics of materials of various brands and carefully studying user reviews.

You need to choose a warm floor under the correct laminate and substrate

In order to choose the right laminate in Moscow, which will be used as flooring on a water heated floor, you need to consult a seller. A careful study of the marking of the proposed models will help to choose a warm floor. Manufacturers of floor coverings place an insert in each packaging of their products containing information on the main characteristics of the goods.

Having carefully read the information insert, you can independently determine whether this type of laminate is suitable for covering a warm floor and not.

It is not difficult to choose a laminate, because almost all modern laminated coatings withstand the maximum temperature of heating of warm floors. Nevertheless, laminate manufacturers provide features that allow the tandem of the laminate and floor heating system to function with maximum safety and efficiency. To choose the best materials, this fact must be taken into account.

In order to choose a laminate suitable for use in combination with a warm floor water system, you need to know the meaning of the symbols indicated on the information insert. The suitability of the material for this purpose is indicated by an icon depicting the contour of the pipe and the inscription "H₂O". The marking confirms that the laminate has passed laboratory tests and can be chosen as a coating on a water heated floor. Such a sign is easy to remember and difficult to confuse with another, because everyone is already familiar with the formula of water from school.

Laminate should be safe for human health. During its use (without heating and when heating a warm floor), it should not emit toxic elements. Sometimes evaporation of the minimum, safe for humans, amount of harmful substances is allowed.

To choose the right laminate, you need to take into account the icons showing the degree of formaldehyde emission. It is better to choose the ideal option: E0 (that is, it is completely absent). For residential premises, you can also choose the emission class E1.

In order to choose the right laminate, in addition to the above characteristics, you must take into account the range of permissible temperatures, which is determined by the manufacturer. Usually it is 27-29 degrees. Thus, the manufacturer of the flooring guarantees the durability of the material in compliance with the specified regime, and warns that it is not responsible for the deterioration of its quality in conditions beyond the specified temperatures.

This temperature range is fully consistent with the recommendations of specialists who strongly advise against heating the laminate above 27 degrees, because higher temperatures can cause a feeling of discomfort. In addition, too much heat leads to deformation of the laminated boards. In addition, formaldehyde emission is activated with increasing temperature.

To choose a laminate for laying on a warm floor, it is necessary to take into account the indicator of thermal resistance of the material. According to European standards, it should not be higher than 0.15 m² × K / W. The larger the parameter value, the stronger the flooring makes it difficult to transfer heat from the underfloor heating system to the room.

Typically, the thermal resistance of a laminate for a water floor heating is 0.05-0.10 m² × K / W. To choose the right laminate, you need to take into account the characteristics of each type of coating indicated in the marking. Thus, the manufacturer helps the buyer to choose the right product. The indicator depends on the thickness of the material and density. The right materials can be selected by calculating the total parameter for the entire flooring (laminate and backing) covering the concrete screed with the underfloor heating system embedded in it.

After determining the thermal resistance of each of the materials, their indicators are summarized. The result obtained is the value of the thermal resistance of the floor covering. For example, a laminate has a thermal resistance of 0.06 m² × K / W, and the intrinsic resistance of the substrate is 0.04 m² × K / W. A total value of 0.1 m² × K / W meets European standards.

To choose the right laminate, do not neglect the above recommendations. Because, if you choose materials with a higher thermal resistance index, there is a risk of overheating of the lower layers, which will lead to deformation of the flooring and activation of formaldehyde evaporation. In addition, the “warm floor” system will not be able to properly heat the laminate, and thermal energy will be spent on unnecessary heating of the base.

If the laminate is mounted on a concrete screed with a walled-in underfloor heating system, it is necessary to use a substrate. It prevents the appearance of an unpleasant creak when the laminate is rubbed against concrete.

The substrate also hides small irregularities on the base of the floor and improves the noise insulation properties of the floor covering. Thanks to this layer, the sounds of household steps and the murmur of water in the pipes of the warm floor become almost inaudible.

Now in construction stores there is a wide range of materials made on various bases that can be selected and used as a substrate. Therefore, from the huge number of proposed options, choosing the most suitable one will not be difficult. Sometimes, to make it easier for customers to choose, they are offered to purchase a complete set of laminate with a backing.

The substrates used for laying under the laminate flooring on the underfloor heating system are often provided with special small holes. Such perforation significantly reduces the thermal resistance of the material, and at the same time does not impair its elasticity an iota.

To choose the substrate correctly, you need to pay attention to the indicators of its thermal conductivity. The higher it is, the better - less heat is retained.

The right choice of substrate will help knowledge of the requirements for these materials:

- Resistant to the maximum heating temperature of the "warm floor" system.

- Environmentally friendly, not emitting harmful toxic substances.

- Leaking steam.

Such qualities are possessed by foamed polyethylene substrates and cork. To choose the right substrate, you need to familiarize yourself with its characteristics.

You can choose canvases of foamed polyethylene, which are very easy to stack. They are available in various thicknesses (including those suitable for laying under a laminate flooring on a “warm floor” system). It is easy to cut the made foam polyethylene, to stick together with a special adhesive tape and to customize under any sizes and forms. The material is affordable, so it is in great demand among buyers.

Due to its relatively high price, cork underlays are less popular. Available in the form of plates or rolls. The material is environmentally friendly, has excellent heat resistance. However, cork is an effective natural insulation, and, therefore, has high rates of thermal resistance. Therefore, the appropriateness of the decision to choose it and use it in the system of water floor heating is in doubt.

You can choose a special perforated narrow-purpose substrate for flooring over the “warm floor” system. It appeared on sale relatively recently, so the range is still not wide. For example, “Arbiton Floor Ther” - a material of Polish origin, is made of expanded polystyrene, has a thermal resistance of 0.06 m² × K / W. Experts recommend choosing this material, consider it more effective than foamed polyethylene. Available in the form of plates and rolls, which allows you to choose the most convenient option for laying.

You can choose a rolled substrate made of foamed polyethylene with aluminum foil coating. Designed to reflect heat towards the floor, therefore, it is placed under the pipes of the underfloor heating system. It is categorically impossible to lay it under the laminate.

Low emission class

During heating, formaldehyde harmful to humans can be released from the laminate. Therefore, give preference to a material with an emission class of E1 or E0.

According to GOST 32304-2013, the production and sale of a laminate corresponding to the emission class E1, in which the formaldehyde content is extremely small, is allowed in Russia. In a laminate with an emission class E0 there is practically no formaldehyde, but the price of such a coating is significantly higher than average.

Laminate on an electric heated floor

The combination of laminate with an electric heater is very popular today.

Pros: simple installation, the ability to control the temperature and set the desired temperature in rooms of various sizes using a room thermostat.

Cons: high cost of maintenance, less security compared to other types of heated floors, dependence on power supply.

Laminate flooring with electric heating must meet the following requirements:

- good thermal conductivity

- resistance to mechanical damage

- high abrasion resistance

- security.

- do not forget to check the marking on the packaging of your chosen laminate - it should “allow” the use of this material on a heated floor with electric heating

- to ensure the highest quality "work" of the electric heated floor, it is necessary to make a perfectly even screed.

Laminate on infrared floor heating

The infrared floor is a thin film with conductive elements in the form of strips. Laminate is the most suitable material for this type of underfloor heating. Moreover, infrared heated floors were created specifically for laying under the laminate.

Pros: modernity, manufacturability, convenience, uniform heating of the surface, comfort and efficiency, since coating of conductive strips with a screed is not required. Such a floor does not dry the air and creates a favorable microclimate in the room. Heats up faster and better than the electric floor, and its maintenance is cheaper.

Cons: the considerable cost of installation, the inability to use in rooms with high humidity, dependence on the operation of the mains.

Laminate for use with infrared heating must meet the following requirements:

- a symbol on the packaging or in the application documents permitting laying on an infrared film underfloor heating

- laminate wear resistance: 33 - 34 class

- laminate panel thickness: 8 mm - 8.5 mm

Tip: do not worry that floor heating will be weak if the film does not cover the entire surface of the floor. For optimal heating of the room it is enough to heat from 40% to 60% of the room area.

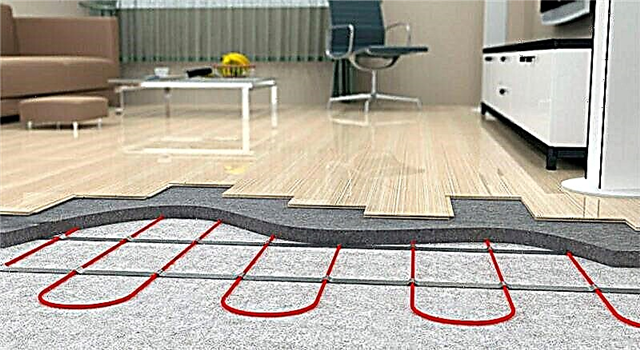

Laminate on the water floor heating

The most common type of floor heating for cottages and cottages, because financially it is much more affordable than other types of underfloor heating. With strict adherence to the installation technology, the water floor will last a long time and will not cause any problems during operation.

Pros: affordable price, independence from electricity, low cost of maintenance, security.

Cons: installation time due to the need to fill the concrete screed and time to dry out, the possibility of condensation during operation, the likelihood of leakage, the risk of loss of tightness, long and laborious repair work.

So that the laminate can well tolerate the "neighborhood" with a heated water floor, choose a high quality material that has the following characteristics:

- H2O marking (or “Warm Wasser”, “Underfloorheating” labels)

- moisture resistance (water resistance)

- high wear resistance: class 33 and above

- thickness not less than 8 mm

- when operating a water heated floor, make sure that the temperature does not exceed 27 ° C

- To prevent overheating, install thermostats on the warm water floor system to organize automatic climate control in each room.

- treat the interpanel joints with a special sealant to make the coating easier to “tolerate” moisture in combination with a sufficiently high temperature.

Laminate with integrated heating system

Ideal if you cannot decide for yourself which laminate is warmer and which type of floor is more reliable and more profitable. The main difference from other types of heated floors is that the heating elements are inside the lamellas, so with this floor covering you will lay down both the floor and its heating system.

This unique innovative laminate has the following advantages:

- efficiency: reduction of heat losses of the material by 25 - 30% due to internal heating

- speed of heating the room: in just 10 minutes the temperature in the room reaches 200C

- the power of one laminated panel is from 40 W / m2 to 70 W / m2 (indicated on the package)

- the possibility of combining heated and unheated areas in the room

- diverse design

The cost of a laminate with an integrated heating system is quite high, but is compensated by a long service life.

- when installing the coating before locking the locks, first connect all the heating elements

- alternate plates of warm laminate with ordinary ones, making separate zones warmed up in the room where you especially need it

- install a thermostat, a regulator and configure appliances to automatically monitor the operation of the underfloor heating in order to save energy.

How to choose a substrate for underfloor heating

Most often, the choice is between cork, polystyrene foam or polyethylene foam. It depends on the budget, as cork underlays are more expensive. However, it is environmentally friendly, resistant to decay, has a porous structure and therefore breathes well.

You will make a good choice if you purchase a special substrate under the expanded polystyrene laminate with perforation, since this material supports lamellas, smoothes out small irregularities, dampens pressing and reduces the risk of damage to the cable, film or water heating pipes, and also has small openings that are in sufficient quantity let heat through.

The underlay for the laminate flooring should have the following characteristics:

- marking

- permissible temperature

- coefficient of thermal resistance (KTS)

- thickness: 1.5 mm - 3 mm

- low material density

- choose a substrate for a warm floor with a thickness of no more than 3 mm in order to smooth out unevenness of the floor, but not to isolate the heating element

- note that the total CCC of the laminate and the substrate should not exceed 0.15 m² * K / W, since the substrate increases the heat transfer resistance.

Characteristics of laminate flooring

Each manufacturer strives to fully meet all the requirements of the market. Therefore, today, popular brands of laminate flooring have models that can be used with underfloor heating. Properly selected material will allow the coating to last a long time and delight the household, warmth and comfort. First of all, it should be noted that special requirements are imposed on a laminate of this type:

- resistance to elevated temperatures,

- low formaldehyde emissions,

- high thermal conductivity

- laminate thickness not more than 9 mm,

- connection of lamellas among themselves by means of locks.

The first requirement is to what temperature the product can be heated without causing harm to it. Manufacturers usually indicate in the instructions or on the bundle the maximum temperature to which the material can be heated (from +27 to +30 degrees). As a rule, the most durable and wear-resistant laminate is able to withstand even critical temperatures.

During heating, formaldehyde harmful to humans can be released from the compressed carrier layer. Therefore, it is worth choosing a material for which the emission class is E1 or E0.

By the way, according to GOST 32304-2013, production and sale of a laminate corresponding to emission class E1 is allowed in Russia.

The thermal conductivity of the laminate characterizes the ability of the material to transfer heat. If the coating has a low level of thermal conductivity, then it is better to use it over the room in which there is no heating. Thus, the material will serve as an additional insulating layer. If it is put on a heated floor, then the system will overheat, and the room will be heated for a very long time. In the end, the warm floor will simply fail.

It is worth mentioning that today all manufacturers offer customers products in which the nominal thermal resistance is less than 0.10 m2 * K / W, which makes its use very effective. In this case, you can choose the most suitable thickness and color scheme.

Also an important aspect when choosing is the thickness of the laminate for underfloor heating. For high-quality coverage, this indicator starts from 7 mm. But you should not follow the path “the thicker the better”, as the coefficient of thermal conductivity of the coating decreases with increasing thickness. 9 mm is the maximum thickness of a material suitable for covering a warm floor.

The glue method of laying the laminate over a warm floor is extremely undesirable. When heating and cooling, the size of the panels changes. The glued panels cannot move relative to the floor. As a result, curvature of the surface of the coating or the appearance of gaps between the panels may occur. It is better to choose a coating designed for the floating laying principle. This will allow it not to deform when heated and cooled. Therefore, the material with a locking connection will be the most optimal.

Do not use carpet flooring on top of a laminate on a warm floor. They impede heat generation and contribute to overheating of the system. As a result, floor heating can fail.

How to choose a laminate for a warm floor?

Choosing a laminate floor for a warm floor is the most common problem that needs to be addressed when planning the installation of underfloor heating in your home. In this case, it is necessary to pay attention to several aspects: to rely on the characteristics described above and choose the material regarding the purpose of the room and the features of heating.

As already described above, when choosing a laminate for a warm floor, you should pay attention to the characteristics: resistance to temperature, thermal conductivity, emission classes and castle connection.

Answering the question of which laminate is better to choose, it is worth saying that you are likely to come across a huge variety of all kinds of types. Installation of floor heating systems will significantly increase the area that will heat the entire room. Thus, the system can quickly warm the room to the required temperature, even despite the resistance of the laminate. The main difference between a warm floor and a conventional radiator is that the second heats the room much longer.Space heating starts from one point - usually from a window or wall and gradually passes into the interior of the room. The warm floor heats evenly.

Almost any type of laminate is suitable for a water floor heating. This type of heating system is most often used in kitchens. It is here that we meet with the whole family several times a day, eat and clean a lot. And since women have to stay here a lot of time, it will be fair to take care of their health and install a warm floor with a laminate.

The most suitable for the kitchen is only a laminate of class 33 and above. It has all the necessary characteristics of wear resistance for the most efficient operation among all other types. High-quality cement-sand screed and this type of laminate will achieve maximum heat transfer. If you pick up a model with improved moisture resistant properties, this will be an ideal option.

Warming of bathrooms is considered one of the trends in modern construction and overhaul. In this case, it is not so difficult to choose a suitable laminate for a warm floor system. Here, the main selection criterion will be the characteristics that are indicated on the product. They will show information on the use of the coating in rooms where high humidity is constantly present. The manufacturer is also required to provide all the data on thermal conductivity, product resistance to damage and compatibility with various underfloor heating systems.

An important criterion for the choice of material is to take into account the characteristics of heating. This means that the selected product model must correspond to the floor heating system of your room, which, in turn, is calculated taking into account the number and effectiveness of conventional radiators used, so as not to overheat the space around.

Common types of underfloor heating:

Consider each type separately.

Laminate on an electric heated floor

Electric floor heating is characterized by high heating intensity. Therefore, the material to be used for coating should be as resistant to heat as possible, and also meet safety requirements. Carefully check the markings on the bundle, allowing the use of the laminate on a warm floor of an electric type. It is advisable to choose a material that can withstand heat up to 30 degrees or more.

Before installation, be sure to check the laminate to avoid "surprises".

Laminate on infrared film floor heating

Electric infrared film heating (IPO) is based on electricity. Therefore, the requirements for this type of laminated coating are almost identical, as in the previous case. However, IPO has a more uniform surface heating than other types of underfloor heating. In addition, it does not require covering the heating elements with a screed, which increases its effectiveness. Laminate suitable for use with infrared underfloor heating, has an icon on the pack or in the instructions for use.

Laminate on water floor heating

The most common type of underfloor heating is considered water. This option is simple and quick to install. There are many models from different manufacturers on the market. The popularity is also so high because this sample is much more affordable financially than other types of underfloor heating.

Laminated boards for this type of floor should contain a special high-quality protective coating that will lie on warm floors. Any system allows temperature differences. This factor is detrimental because condensation occurs as a result of such drops. As a result, products will begin to change their dimensional characteristics. Therefore, the quality of the entire construction of a warm water floor will be directly affected by the selected laminate. So which one to choose? The answer is simple: a thinner and moisture resistant coating should be used.

The fact is that water-based systems are not only prone to condensation, but can also lose their tightness over time. As a result, the entire floor structure or part of it will be flooded with water. If you use improper material, you just have to throw it away. High-quality laminated panels after drying will return to their previous forms and characteristics.

Unfortunately, in systems of water floor heating, there is always a chance of a leak or complete depressurization of the circuit. Therefore, many owners opt for ceramic tiles.

Tip: Put the thermostat on the underfloor heating system. This will help prevent overheating of the water circuit and will allow better control of the indoor microclimate. And also it will have a positive effect on the laminate covering the warm floor.

Laminate with integrated heating

Some manufacturers offer the market an innovative laminate with integrated heating. The flooring contains heating elements. The effectiveness of this development has not yet been appreciated by all customers, since many are simply afraid to buy a new product.

Each laminate flooring with integrated heating has its own power per square meter. The spread in the values of this parameter is from 40 to 70 W / m2. This information is indicated by the manufacturer on the packaging, therefore, there will be no problems with the calculation of thermal power and electricity consumption.

Laminate with built-in underfloor heating has several advantages compared to a conventional electric underfloor heating covered with a laminate:

- Since the heating elements are not in the screed, but in the thickness of the material, the efficiency of the system increases. When turned on, warming up is from the inside, faster heating the air masses in the room.

- Due to its construction, the heat loss of the material is one third lower than the standard.

- When laying, you can use the boards of a conventional laminate. Thus, it will be possible to create zones without heating, if necessary.

- The installation of a thermostat and a regulator will significantly save energy.

Substrate Selection

Laminate for a warm floor, like a regular one, is laid on a substrate that performs four main functions:

- protection of the coating against wear during friction against the screed,

- eliminating squeaks when touching the material on the screed,

- correction of small irregularities on the prepared surface,

- additional sound insulation.

The use of a substrate over a warm floor should not violate the temperature regime. In addition, the substrate material must be environmentally friendly, since a lot of heat will be released during floor heating. Poor quality products can produce an unpleasant odor.

As a result of heating and cooling under the laminate, condensation may collect. In order to prevent the development of mold and damage to the coating, the substrate should not impede the evaporation of moisture. Therefore, it is important to choose a material that has good vapor permeability. The cork backing is best suited for such purposes. It has a porous structure and therefore breathes very well. However, this is a very expensive material. You can save by using synthetic substrates made of foamed polyethylene or polystyrene with perforation.

Remember that the substrate has its own thermal resistance, which depends on its thickness. This information can be found on the packaging of the material. In order to prevent overheating of the floor heating system, the total thermal resistance of the substrate and the laminate should not exceed 0.15 m2 * K / W.

Features of installing laminate flooring on underfloor heating

Laying the laminate is done only after the base is perfectly aligned. If this step is completed, you can proceed with the installation process.

In the process of laying on a warm floor, some rules must be observed:

- The screed must dry completely. If you are not sure whether it has dried or not, it is better to wait a little longer. This usually takes 1 to 4 weeks. Believe me, too many mistakes have been made at this stage, not to say so.

- Laying of the laminate is done only on the proven floor heating system. It must be started and warmed up to operating temperature. Only after making sure that everything is in order, the underfloor heating must be turned off and wait until it cools down to room temperature. Only after thorough testing of the configuration of the heating system can start laying.

- Packs of material should lie down for at least 3 days (preferably a week) in the room where they will be mounted. It is necessary that the laminate boards accept the temperature and humidity of the environment and do not change their geometric dimensions after installation.

- Installation of the laminated coating is carried out at a temperature of at least 16 and no more than 32 degrees Celsius on a cold base.

- After laying the laminate, you should turn on the warm floor and gradually increase the temperature to the desired value, increasing by 5 degrees per day.

It is easy enough to lay the material on your own. Laying is carried out according to the same rules as for a conventional laminate.

Output

There is nothing difficult in choosing a laminate for a warm floor. Look for the appropriate marking on the bundles of material and in the instructions for use.

Laying a laminate on a warm floor is even a layman's power.

Remember that the laminate must not be heated above 27 degrees. Therefore, the warm floor is only an auxiliary source of heat, but not the main one.

Strict adherence to all the tips described in the article guarantees a high-quality, durable and comfortable floor, on which you want to lie down, and not just walk around!

How to choose and lay a water floor heating under the laminate

To choose the right underfloor water heating under the laminate, you need to know the order of its installation. When laying the foundation, on which it is planned to place the "warm floor" system, it is carefully leveled and protected from moisture from the outside, and in case of an accident through a leak to the floor floors. Then the base is well insulated to exclude heat loss on its heating. To do this, foil insulation is used that directs the thermal energy emanating from the “warm floor” system to the side of the laminate.

A reinforcing mesh with cells of 80 or 100 mm is laid out on the insulation, on which the contour pipes of the “warm floor” system will be fixed.

Instead of a metal mesh, you can choose insulating mats with a profiled surface. They are equipped with special bosses intended for laying pipes of the “warm floor” system between them. This design is very convenient for installation, but is not cheap.

After laying the contour pipes of the “warm floor” system and checking their tightness, proceed to pouring the concrete screed. As a rule, concrete is poured with contours filled with water in order to protect the pipe walls from deformation under the weight of concrete.

Most often, water floors are poured with a monolithic concrete screed with a thickness of 50 ÷ 70 mm. But you can choose a "dry" technology, which uses heat transfer metal plates. This technique is easier to install, but less effective.

Before choosing a warm floor for a laminate, you need to familiarize yourself with the characteristic features of laying a laminate on a "warm floor" system.

The laminate is laid on a perfectly dried screed. Before installing the floor covering, a trial run of the “warm floor” system is necessarily carried out, which helps to more thoroughly dry the concrete screed throughout the thickness.

Recommended articles on this topic:

It is allowed to start the “warm floor” system into operation no earlier than three weeks after pouring concrete. In addition, it is recommended to withstand about two more weeks between the start of the “warm floor” system at maximum power and the laying of the laminate.

After the start of operation, the temperature of the coolant in the pipes is increased gradually - every day no more than 5 degrees. Upon reaching the calculated level of floor heating, for a couple of days the “warm floor” system is kept in this temperature mode, then the heating is turned off.

Installation of the laminate should be carried out at normal flooring temperature, that is, when the "warm floor" system does not work. The ideal option is to lay the laminate in the warm season. The optimum surface temperature of the concrete screed at the time of laying the laminate is 15-20 degrees.

You need to immediately determine the direction of laying the laminate boards. Experts recommend choosing a method for orienting them according to the rays of light penetrating the room through the windows. Therefore, boards should be laid parallel to walls that do not have window openings. This way of laying emphasizes the decorativeness of the laminate, and the joints between the laminate boards makes it less noticeable.

The laminate introduced into the room must adapt to the microclimate of the room - lie down for at least 48 hours at an air humidity of not higher than 65-70%. For best results, remove the factory packaging film from the laminate bundles.

It is advisable to immediately draw up a diagram of the cutting and layout of the boards in order to avoid mistakes. It will be great if the piece of wood remaining after laying the first row fits perfectly at the beginning of the next. However, it should be remembered that it is not recommended to use pieces of laminate boards with a length of less than 300 mm.

The first board should be laid so that the groove is on the outside. The spike from the other end located near the wall is cut off. However, one should be very careful here. You need to immediately calculate which board will fit in the last row. If its width is less than 70-80 mm, it is better to narrow it at the beginning, so that at the end the laminate boards are of normal size.

How to choose and install an electric floor heating under the laminate

In order not to make a mistake when buying, you need to know how to choose a warm electric floor under the laminate.

For floor heating, you can choose an electric heated floor, which is suitable for any type of flooring. This type of heating system (with the exception of the self-regulating cable) must be connected to the thermostat. You should also choose a method of manufacturing a screed (dry or wet), on which the heating wire is laid.

Thanks to the laying technology, the cable underfloor heating creates an ideally even base for the subsequent installation of the floor covering.

The principle of operation of the self-regulating heating cable is based on the use of a special matrix, which allows you to control the heating temperature without using a thermostat and select the optimal temperature regime automatically.

Installation of an electric heated floor under the laminate is as follows:

First, the base is prepared - the floor surface is leveled, its waterproofing is provided.

Then, a heat-insulating coating is laid - a foil substrate with special marking that facilitates the process of laying the cable.

Thermostat is being installed. Installation and operation of an electric floor heating under the laminate is impossible without sensors and a heating temperature controller.

The cable is placed according to a pre-compiled scheme. Pre-calculated length, pitch and cross-section of the cable. During the layout between the turns of the wire, a temperature sensor is mounted, placed in the corrugation.

Screed is made. You need to choose a method of manufacturing a screed (dry or wet). Perform a screed in the selected way, in which the warm floor under the laminate will be laid.

According to the speed of manufacture of the screed, the dry method has certain advantages. If you select it, then you can lay the cable the very next day after performing a dry coupler.

If you choose the wet method, you will have to spend more time.However, it is very popular because many people prefer to choose it because of its ease of implementation.

The next step is the flooring. Laying a laminate requires a certain skill and precise implementation of recommendations. For example, you have to cut laminate boards (the allowable length of the board should not be less than 20 cm).

When laying the laminate, it is necessary to leave a compensation gap along the walls (0.5-1 cm). Before installation, the laminate needs to be brought into the room, unpacked and left for a day for its adaptation.

The order of installation of the "warm floor" system may differ depending on what type of heating to choose and manufacturer's recommendations.

How to choose and mount an infrared warm floor under the laminate

Many buyers prefer to choose an infrared (also called film) warm floor under the laminate. To choose such a floor, you need to know its properties. The relatively small thickness and uniformity of the laminate boards contribute to the effective distribution of infrared rays over their entire surface. The design features of the film floor prevent the penetration of infrared radiation deep into the base, thereby providing high efficiency.

The principle of operation of a film underfloor heating is based on the application of special technology using the features of bimetallic alloys. When the unit is connected to the mains, an electric current passing through bimetallic compounds causes the appearance of infrared radiation.

To choose an infrared warm floor under the laminate will help knowledge of its properties. Such a warm floor gives the floor a modern look. The functionality of the “warm floor” system is to create a comfortable indoor microclimate all year round and at any time of the day. You can install your own infrared floor heating on your own. Moreover, this will not require expensive technology and the manufacture of concrete screed.

To choose the right film underfloor heating under the laminate, you need to know that the infrared film is classified by the type of heating element, which can be of two types:

Carbon film is considered more durable and elastic.

The following materials and tools will be required for laying an infrared warm floor:

- a substrate for a laminate with a heat-reflecting coating,

- infrared film,

- temperature sensors

- temperature regulator

- electrical wiring

- set of fasteners-clamps for installation of paintings,

- insulation kit for installation,

- polyethylene film for protection against moisture,

- plumbing tape

- wallpaper knife

- scissors,

- metal ruler,

- measuring tape,

- a simple pencil.

General rules for installing a "warm floor" system:

- Keeping a distance. The “warm floor” system is installed at a certain distance from sources of heating (fireplace, stove, battery, etc.). Usually the minimum distance is 50 cm.

- Free space. Installation of infrared underfloor heating under the laminate is allowed to be made in an empty place. Customer reviews confirm that installing a “warm floor” system under furniture leads to floor overheating.

- Availability. It is necessary to choose a floor covering that will not impede monitoring the condition and functioning of the installed “warm floor” system.

- Ventilation. Laminate has a low thermal conductivity. Therefore, a laminate flooring is provided with high-quality ventilation, which also depends on the correct installation of laminate boards.

The main requirement for laying the "warm floor" system is the presence of a perfectly even base - without bumps, pits and cracks. In addition, the room must have a 220 volt electrical outlet. Only after making sure that the premises meet the requirements, you can proceed to the following actions.

Step 1. Base cleaning. Cleaning work is carried out to remove debris and dirt. To improve the result, it is recommended to use a vacuum cleaner.

Step 2 Measurements. It is necessary to measure the size of the room and calculate the required amount of material to be laid. Overlapping IR film is not permitted. Therefore, if it is not possible to lay the whole stripes, then you can leave small gaps between them.

Step 3 Installation of heat-reflecting substrate. When laying an infrared warm floor under the laminate, a special heat-reflecting substrate is used, which is laid on the floor throughout the room. If you select a material that is too large, you will have to shorten it.

Step 4 Processing joints of the substrate. It is necessary to glue the joints of the heat-reflecting substrate. The sizing is done on the outside of the material using adhesive mounting tape.

Step 5 Preparation of a heating film. In accordance with the size of the room, you need to cut the infrared film of the "warm floor" system. The cuts are made strictly in the areas painted white.

Step 6 Laying the film. In a room freed from furniture, heating film is laid across the floor. In the presence of furniture with a film of the "warm floor" system, only empty seats are covered.

Step 7 Tire insulation. In places of cuts of the film, it is necessary to insulate the tires from copper. This is done with electrical tape, twisting it through the place of cut. It is important to ensure that no air gets under the tape.

Step 8 Processing a ground bus located in the center of the heating web. It needs to be bent from two sides, trying not to touch the slices and the remaining white areas.

Step 9 Insulation of the film in the area freed from the grounding copper bus. For insulation, a special electrotechnical adhesive tape is used. It should be glued in such a way that there is a bend inside out.

Step 10 Insulation of sections of the infrared film of the "warm floor" system is carried out with adhesive tape. It is glued half width and then bent through a section of the film.

Step 11 Aligning the film of the "warm floor" system at the location of the layout and fixing to the substrate from the side opposite to the temperature controller.

Step 12 Soldering wires connecting individual parts of the film. The film of the “warm floor” system needs to be bent from the side where the thermostat is located, so that the wrong side is up. For the convenience of work, it is allowed to temporarily fix the film with mounting adhesive tape. Then prepare the materials: installation cable with a cross section of 2.5 m2, solder and a soldering iron with a capacity of not more than 60 watts. Protective tires located at the edges of the film are stripped of insulation. The edges of the slice are marked with a soldering iron, the insulation is melted and it remains to clean with a knife.

Step 13 Joining sections of IR film in parallel by soldering. The installation wire must be stripped of insulation in an area sufficient for soldering. In this case, the wire core is not cut. You need to connect the sections of the film, guided by the rule "phase zero". It is better to choose a wire with a multi-colored insulating layer. When soldering, it is necessary to ensure that there is no strong tension and crossing wires. Otherwise, their breakage and damage cannot be avoided.

Step 14 Insulation of soldering points. All soldering points are insulated with electrotechnical adhesive tape.

Step 15 Installation of a temperature sensor for underfloor heating. The temperature sensor is installed under the film, in a pre-made recess in the heat-reflecting substrate. It fits in the center of the working area, and you need to choose the warmest place in the room. Compliance with these requirements eliminates the risk of overheating of the film. The wire from the sensor kit is laid along the substrate to the thermostat, fixed with mounting tape.

Step 16 Wire stripping, tinning of their ends and connection to thermostat terminals. Similarly, you need to connect the power cable and the installation wire that goes to the heating busbars.

Step 17 According to the previous algorithm, grounding buses are connected. Tires are stripped, trimmed and joined with copper strips or cable. At the output, the wires are enclosed in a corrugated pipe.

Step 18 Fixation of the film system "warm floor". Fastens the film on the substrate using mounting tape. At the same time, it is not allowed to lay individual sections of the film of the “warm floor” system with an overlap.

Step 19 Fastening the ground wire removed from the corrugated pipe to the ground terminal of the temperature controller. If there is no regulator, then the cable is attached to the ground loop.

Step 20 Before laying, the functionality of the “warm floor” system is checked. Installation of infrared film underfloor heating under the laminate is made only after a trial run. To do this, you need to connect the “warm floor” system to the 220 V power supply network, put the thermostat in the middle position, move the toggle switch to the working position. Let it work for no more than a minute, and by hand touching all parts of the film of the “warm floor” system, assess the degree of heating.

Step 21 Cleaning up. It is made to remove scraps of the wire and other debris. From devices that improve the quality of cleaning, you can choose a vacuum cleaner.

Step 22 Laying a plastic film to improve waterproofing. The IR film of the “warm floor” system is covered with a film of polyethylene (more than 160 microns thick) so that an “influx” of film onto the walls of 15-20 cm is formed.

Step 23 Laying laminate flooring.

To cooperate with My Repair Company is reliable and prestigious. The professionals working here are top-notch professionals. The company "My Repair" works throughout Moscow and the Moscow region.

Are you afraid that starting repairs, it will never end?

With the company "My Repair" this will not happen.

- Clear deadlines. We will refund 5% of the order amount for each day of delay,

- Quality assurance. All unforeseen expenses are compensated at your own expense,

- Fixed estimate. The cost of work will not increase. Immediately fix the price in the contract,

- Installment plan 0%. No down payment. Start the repair right now,

- Free design project. Design project and 3D visualization of your apartment.

Request a call and find out the cost of your repair!

What kind of warm floor is better to use under the laminate

In simple terms, a laminate is a panel of pressed and glued cellulose fibers. They are protected from aggressive influences by a substrate, a decorative film and chemical additives, and are stacked without attachment to the base.

From this definition we can conclude:

- Laminated panels do not conduct heat well.

- The substrate further reduces thermal conductivity.

- The wood-fiber structure significantly expands-tapers when heated-cooled.

- With increasing temperature, toxic substances may be released.

At first glance, such a flooring is not the best choice when it comes to the need for a warm floor. However, negative factors can be, if not completely eliminated, at least minimized by observing simple conditions. For example - having bought a suitable laminate, limiting the temperature to 25-27 degrees, choosing the right floor heating system correctly.

Important: in fact, any system is suitable, but some of them seem to be created for the laminate.

Water heated floors

Electricity is the most expensive source of heat, even taking into account nightly and other preferential rates. Therefore, water fuel boilers (especially gas) are not only efficient, but also economical. In combination with laying the pipeline under the floor, this heating method is sometimes optimal.

Sectional underfloor heating.

But it also has disadvantages:

- obtaining permission for installation in an apartment building is a lengthy, costly procedure,

- design, installation - labor-intensive processes requiring skills and special equipment,

- the price of stop valves is comparable to the cost of the remaining elements combined,

- laying of the pipeline involves the installation of an insulated thick layer screed,

- control, management (for example, zoning of space) is complicated by the complexity of the system as a whole,

- low maintainability associated with significant waste of time and money.

It is advisable to equip a water heated floor in a gasified private house and it is best to do this even at the stage of building a house. When installing a water heated floor during repair work, you must be prepared for a large amount of dust and dirt. As a rule, when arranging a warm floor in a private house, it is mounted in all rooms, which makes the entire system more economically feasible.

Heating electric cable

The heating (resistive) cable works on the principle of a closed conductor with an unchanged resistance, which heats up when power is supplied. The section (section) ready for installation is usually wound into a bay, while the section power is calculated along the length. It is simple, reliable and inexpensive, and its efficiency depends, for the most part, on installation technology. If everything is done correctly, cable heating is quite economical, efficient, even in comparison with water. Regulators (thermostats) are also available and easy to install. Therefore, difficulties with control and management does not arise.

Arrangement of a heating cable under the laminate.

However, the disadvantages, however, are:

- system volatility,

- the need for complete immersion of the heating element in the screed,

- the need for a full-fledged “pie” device, including insulation and concrete screed,

- low maintainability,

- inadmissibility of overheating associated with overlapping of the cable or its suboptimal location relative to furniture, household appliances, etc.,

- failure of the entire section if one section is damaged.

You can say that a resistive cable is a good option. One could stop at it, however, when using it, it would be necessary to equip a concrete screed with a height of 3-5 cm. If the screed is already flooded and raising the floor level is impossible, the use of a heating cable is not advisable.

Electric heating mat

Heating mats are a fiberglass or plastic mesh on which the same resistive cable is fixed. It is twisted into rolls convenient for installation, and the canvas can be cut by adjusting to the shape of the room. The distance between the turns of the heating core is uniform and optimal here, which greatly simplifies installation.

Arrangement of a heating mat under the laminate.

A major advantage of cable mats is also the compactness due to the thickness of the cable. Thin thin sections (3-5 mm) do not require the installation of a thick-layer screed. Therefore, they are often laid, for example, immediately under a ceramic tile. With the laminate, the situation, of course, is different - here you can not do without screed (1.5-2 cm thick). After all, a cable that is not immersed in an environment that removes heat will burn out.

Almost all the flaws inherent in the cable in the bay are observed in the case of heating mats.

Aluminum Electric Heating Mat

Aluminum mats are a significantly modified analogue of cable mats. Here, the heating elements are already immersed in a medium that removes heat - dense aluminum foil. The cable is not round, but flat, so there are practically no protruding parts on the working surface. A significant part of the heat is transferred in this case by radiation reflected upward by the foil. Therefore, the use of thermal insulation to reduce heat loss is optional (but desirable).

Aluminum heating mat laid on the base.

Aluminum mats are designed for laying immediately under the floor covering, which is not attached to the base. Including - under a laminate, a parquet board, linoleum, etc., even in damp rooms.In any case, the complexity is minimal - spread the mats, laid the temperature sensor, connected the system to the thermostat. All main connections are made at the factory or prepared for simple and quick switching. An additional plus - a solid foil almost completely absorbs electromagnetic radiation and is a grounded circuit (if connected correctly).

The device is an aluminum heating mat.

The disadvantages of this product include the high price and, as a consequence, the likelihood of fake brands.

Answering the question, what kind of underfloor heating is better for laminate flooring, we can say with confidence that aluminum heating mats are the best solution.

Film underfloor heating

A film floor is several layers of a dense polymer film glued and twisted into a roll. On the inner surface of one of them graphite (or other carbon) markings are applied. It is a parallel strip about a centimeter wide, connected at the edges of the sheet. The web thickness is 0.5-2 mm, depending on the model, and the roll width is usually 0.5 m. This film is also called infrared, and this is explained by the fact that more than 70% of the heat is transmitted by radiation in the infrared range.

Laying a laminate on a film underfloor heating.

The main advantages of infrared film:

- compactness, lack of protruding parts,

- simplicity, speed of installation, connection,

- responsiveness of control and management,

- unnecessary additional insulation (in addition to the heat-reflecting layer),

- high heating rate of surrounding objects,

- electricity consumption is 20-30% lower than cable floors.

At the same time, the heating sections are connected in parallel, and if one fails, the others will continue to work. In addition, the film can be cut by repeating the geometric shape of the room. Therefore, installation is as simple as laying aluminum mats, but the film is more compact and, as a rule, cheaper.

The disadvantages of infrared film are standard for electric heating. For example - inadmissibility of artisanal compounds, overheating, lack of self-regulation (in most models). But low mechanical strength, inadmissibility of laying in damp rooms are added to them.

The IR film does not require the installation of a screed and fits directly under the laminate, it saves energy, but some models are not designed for use in humid rooms. However, the laminate itself is also not laid in rooms with a humid microclimate.