- area and weight of the gate,

- type of beam and roller system (the ease of movement of the sash depends on it),

- literacy when installing sliding gates, lack of distortions.

- frequency (intensity) of operation,

- climate and time of year when the drive will be used.

Thinking about what automation to choose for sliding gates, it is also necessary to consider a number of parameters:

- Power reserve. It must be large, otherwise the drive may not work in winter conditions.

- Gear material in the gearbox. The most reliable are metal.

- Voltage drops or undervoltage.

Web weight when choosing an electric drive

Standard 4 * 2 gates filled with corrugated board, 3D mesh, and a bar weigh about 150 kg. For them, under good operating conditions, you can use a drive with a force of 400-500 kg. For example, CAME BXL or Alutech RTO-500.

If the same gates are sewn up with wood, or mistakes were made during installation, the gates go hard - we recommend using drives with great effort. For example, CAME BX-608AGS (800 kg), Alutech RTO-1000 (1000 kg), Doorhan Sliding 800 (800 kg)

For gates with a width of 5.5–6 meters, especially for heavy filling (wood, forging), we recommend using the CAME BKS-12AGS (1200 kg), Doorhan Sliding 1300 (1300 kg), Alutech RTO-1000 (1000 kg) drives.

Operating intensity

Intensity is expressed as a percentage. Drives are divided into 3 types:

- intensity 25-30% (CAME BX 608, Alutech RTO-500, Alutech RTO-1000,) Suitable for domestic use.

- intensity 50-70% (CAME BKS12, Doorhan Sliding 800, Doorhan Sliding 1300). Suitable for domestic use and for installation on the entrances of public areas.

- high intensity (CAME BXL, CAME BX-246). Suitable for light gates at the entrances to gardening, public areas.

In practice, if you install a drive with an intensity of 25-30% at the entrance to gardening, then it will overheat, the thermal protection will work and you will have to wait for the engine to cool.

Drive power

The characteristics of the electric drives indicate what weight the wings are designed for. Manufacturers advise using automation with a power reserve of 30%. Firstly, working at full power, the drive will become very hot and wear out faster. Secondly, if the gates are completely sewn up, then the mechanism will have to overcome the wind resistance, respectively, more power will be required. And, thirdly, in winter the load on the drive increases, the voltage in the network drops and without power reserve, he will not be able to pull the gate off.

Manufacturer's choice

Today, Chinese and European manufacturers of automation compete in the market. There are also domestic brands produced in cooperation with China.

Most Chinese automation systems are focused on minimizing prices, which reduces the quality and service life of finished products. But there are pleasant exceptions. For example, manufacturers Alutech and Doorhan. By choosing the automation of these manufacturers you get modern and reliable equipment at an affordable price.

Of the variety of European manufacturers, the Italian company CAME deserves the most attention. This brand has been manufacturing reliable and high-quality automation kits since 1972 under the constant supervision of European organizations over the quality of products and compliance with safety standards. In St. Petersburg there is a service center CAME. In which installers and managers are certified.

Each for himself decides what automation for the gate to choose. However, we do not recommend purchasing “nameless” products. No one knows how long it will last and how much repairs will result in the event of a breakdown. The automatic system is bought for a long time, so it is better not to save on it.

What will affect the selection of automation

Of course, the features of the gate should be unlocked first of all when you want to install automation on your sliding structures. If you make a selection without preparation and buy the first rollback system that comes across, then there is a big risk that it will absolutely not help you to cope with the task and simply will not be able to budge large and weighty gates.

Automation kit for sliding gates

So first of all, you must take into account a number of the following reasons when automatic equipment for sliding gates is selected:

- The mass of the movable component of the fence.

- Parameters of the installed counterweight.

- Weather conditions under which the system should work properly and stably.

- The quality of the hardware that is used at your gate.

- Installation quality.

- Intensity of use of the entire structure.

Now let's take a look at all of the above criteria in order, so that you can get a clearer and more detailed picture.

The mass of the rolling structure

Let's start in order with the mass of the sliding structure of the gate. This indicator is one of the most important and most of all affects the selected automation for them. The larger the nominal mass, the greater should be both power, since the internal filling, which is responsible for the movement and takes all the burden on itself.

Counterweight Parameters

Based on the parameters of the counterweight, you should select the maximum possible length that the automatic system motor can pull better. As a rule, the counterweight is approximately seventy percent of the length of the gate itself, so when choosing automation, you need to add the length of the counterweight to the length of the gate, and you will get the minimum size that the automation should pull.

Climatic conditions

You also must take into account the weather conditions that may be in your area. This is especially important in those regions where very high humidity and rains occur for a significant part of the year.

In Siberia, in some cases it may be necessary to install additional heating.

In addition to moisture, it is necessary to take into account the minimum temperatures that can occur in the winter season, and how long these temperatures are held. Given all these criteria, your mechanics should withstand such weather conditions without problems and work stably and without failures.

Hardware Quality

Given how high quality fittings you have installed on your gate, you should better adjust the possible performance of the motor. For high-quality chi of expensive accessories, it is quite enough not too powerful motor, without any amplifiers and auxiliary modifications.

For bad accessories that open the gates with fairly strong friction and labor, then you need to choose a motor that can withstand increased loads and has great traction ability.

Quality of installation and intensity of operation

The selection of automation also depends on the quality of installation. The more evenly and most accurately your new retractable guards are installed, the less effort the opening mechanism must make.

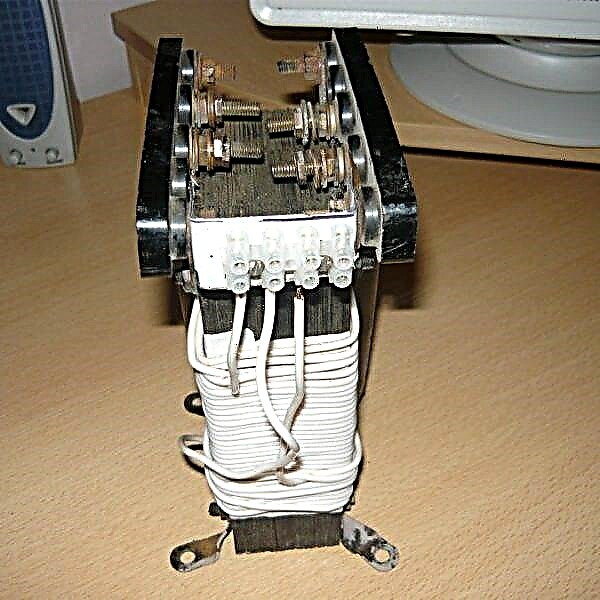

Use of plastic gears in gearboxes: 100% guarantee to reduce the operating period of automation by 3 times.

The intensity of entry use will be the second most important criterion, after the mass of the rolling structure. Came automation for sliding gates must have wear-resistant parts in order to better withstand the increased operating conditions.

For less frequent use, nice sliding automation can have less resistant elements in the structure and therefore have a price significantly lower.

We make the right selection

To make the right choice, and ultimately get a quality newly purchased product, you need to pay attention to such indicators as:

- Power.

- Secondary functions.

- Price and quality.

- Appearance.

Video: Basic selection options, tips

Power and Health Indicators

Power will be of key importance and absolutely all performance indicators will depend on it. The higher the mass of the structure that needs to be moved, the larger the size, better or worse the quality of the fittings, weather conditions and more.

For a gate weighing 400-600 kg, an 800 kg drive is optimal. And for heavy gates up to 1100 kg, the CAME BK 1200 model is suitable, for light 300 kg - Doorhan Sliding 300.

Also, the greater the rated power the motor will have, the more electricity it will need to consume to operate. If you buy automation that is significantly more powerful than you need, the more unnecessary costs you will be wasting when starting up systems. So pick it up as accurately as possible and with only a small margin.

Additional functions

For special conditions, when there is a risk that auxiliary functions will be required for the system to work, it is better to immediately anticipate this and think through it in advance. That is, if there is a risk that the hardware will freeze, then buy a motor with a gain function, then it can easily stretch the icy wheel.

Auto close function: convenient function, the gate will close after the set time has elapsed even if you forget to press the button.

If you need the gates to open very quickly, then you need to buy automation with acceleration functions. For wider gates, mechanisms that are modified to work with long fences will be required.

Value for money

Price and quality should always be inextricably linked. If you see a frankly bad and loose mechanism and at the same time its price is very high, then you should definitely refuse such a purchase.

Chinese automation in general can work just as reliably as Italian. The choice is only in the ratio of price / quality.

Value for money should always be inextricable and meet all reasonable boundaries. Even if you do not have problems with money, you still should not rush to the most expensive. You must always pay attention first of all to the build quality, performance and compliance with your needs.

The appearance of the design

The last thing you need to choose the look. It should be suitable in color and material to your design of the fence, landscape and the house itself. It is inappropriate to use a bright color, when dull colors predominate in the design.

Also, for metal fences, metal products in its natural color are not suitable. You should select a texture that will be as similar as possible to wood.

So, so that the automation for sliding gates would suit you as clearly as possible, and you spent a lot of money with the greatest productivity, rely on criteria such as the device’s power, the conditions under which it should work, and the intensity of the system.

Experts recommend that you select all of the above criteria as accurately as possible, only the power can be selected a little with a margin so that it is definitely enough.

Factors affecting the choice of automation for sliding gates

It is difficult to answer the question of how to choose automation for sliding gates, but you can, if you know what to look for when buying. It is necessary to consider all factors, and a considerable number of them:

- the area and weight of the canvas

- type of the supporting system (the ease of movement of the sash depends on it),

- the geometric correspondence of the fixed elements (is the structure installed correctly: the distance between the roller bearings is measured),

- counterweight size

- frequency (intensity) of operation,

- climate and time of year when the drive will be used.

Thinking about what automation to choose for sliding gates, it is also necessary to consider a number of parameters.

- Power reserve. It must be large, otherwise the drive will not work in adverse climate conditions.

- Gear material in the gearbox. The most reliable are metal.

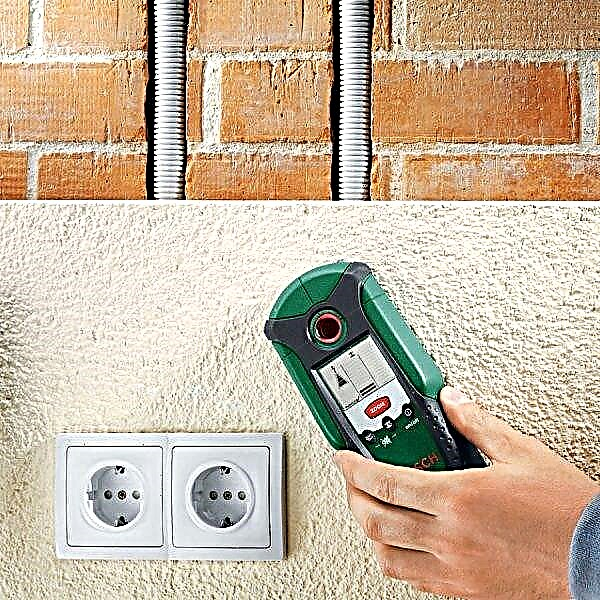

- Type of limit switch. When operating the gate in winter, a magnetic one will be the best option. The mechanical type freezes in the cold, preventing the gate from opening.

Attention! The use of plastic gears in the gearbox reduces the life of the drive by three times.

Counterweight Size

In this context, we are talking about cantilever (self-supporting) sliding gates. The counterweight balances the canvas. Usually it is 40-50% of the size of the opening. If you take a reduced counterweight, then the load on the roller bearings and the friction force will increase. The mechanism will need more efforts to open and close the gate, which in the future will negatively affect its service life. In the case when the counterweight is less than 40%, the one that has a larger power reserve will answer the question which motor is best for sliding gates.

The choice of automation depending on the type of gate

The standard automation kit includes the following "stuffing":

- gate drive

- Control block,

- access control system, more fulfilling the role of a security device.

The drive, in turn, is electromechanical or hydraulic. The first is simple in design and budget cost. Repair and maintenance of such a device are cheap. The hydraulic drive design is more complex, and it is much more reliable. A person whose choice fell on this automation for the gate will have to fork out for installation and maintenance.

Regardless of the type of construction, any automatic drive is equipped with a protective system against interference in the power supply network. The built-in blocks regulate the speed of movement of the valves through force sensors and locking devices.

Each type of door has its own type of drive. And for the design to work harmoniously, it is necessary to make the right choice in favor of one or another automation.

Drives for sliding gates

For these designs, only one type of automation is used. It consists of an electric motor, gearbox and gear, which transfers force through the gear rack to the wings, which makes the latter begin to move. The drive itself is mounted on a foundation near the gate or on a specially made pedestal. When deciding which drive to use for sliding gates, the weight of the sash must be taken into account. This is a binding decision.

Automation for sectional doors

When arranging sectional structures, the weight and area of the sash are taken into account. Automation of such gates involves the use of two different mechanisms - a chain or axial drive. The first is applied to lightweight and small-sized canvases, for example, in cottage garages. The force generated by the chain (ceiling) drive is transmitted to the web to be lifted via a chain drive. This mechanism is mounted with a reduced, inclined or standard method, taking into account the height of the paintings and the direction of rise. An axial (shaft) drive is produced for large gates with a high frequency of use.

Operators for swing gates

It is difficult for a person without experience how to choose automation for swing gates. In this matter, it is important to be guided by such parameters as the effective area of the canvas and the predicted wind load. Automation of swing structures is carried out in the following ways:

- lever

- linear

- underground installation system.

The most popular is linear automation. The peculiarity of the installation of this device is that it is mounted only on gates with a gap of 6-8 cm from the canvas to the point of attachment of the drive. When the installation of linear systems is not possible, the choice of lever automation for swing gates is the most optimal solution.If the canvas and the appearance of the structure do not accept such clutter (high artistic value), then the only possible option is an underground installation system.

Equipment

Of particular note is the snap-in models with additional devices. An important role is played by the presence of several access control panels and the ability to simultaneously control several shutters from one remote control.

Modern drives for sliding gates can be used not only to pass cars, but also to pass people (wicket mode). Some models are equipped with a partial opening function: the leaf moves to a predetermined passage width.

Photocells are a component of a security system consisting of two devices - a transmitter and an infrared beam receiver. They are mounted on opposite poles and fix various obstacles that impede the movement of the sash. Catching an obstacle, the automation beam immediately cancels all the given commands and completely stops the current task.

The purpose of the warning light is to draw attention to the movement of the sash and to inform others. Having received a signal from the remote control, the lamp starts flashing and the gate starts to move. Some electric drives carry out self-diagnostics. If a malfunction is detected in the system, the signal is sent to the lamp.

When deciding which automation drive for sliding gates to choose, it is worth considering that when ordering a gate and an automation kit, the overall price tag will be lower than if you buy everything separately. The savings are associated with reduced shipping and installation costs.

Conclusion

Automation of gates is one of the main tasks that arise when arranging entry to the territory. The life of both the automation kit and the design itself depends on a properly selected drive. Therefore, it is very important to pay attention not only to the quality of the electric drive and the gate, but also to their parameters and technical characteristics.

The nuances of choosing an automatic gate

The first thing to understand before ordering automation for gates is that it is installed for a very long time, so you need to choose it carefully.

We highlight the main mistakes of the customer:

- conclusion of an agreement with unverified firms,

- purchase of equipment without installation,

- absence in the contract of clauses about a guarantee and service,

- order installation of automation separately from the installation of the gate.

The Internet is full of announcements on the supply of equipment for entrance and garage doors, but few companies are truly professional. Before you visit the address indicated on the site, be sure to read the reviews not only on the site itself, but also in the search, contact the company, find out in detail about automation and documentation for it.

Many companies use the eminence of the supplied equipment and do not consider it necessary to monitor the quality of the services they provide. One of the most common problems with such firms is the lack of clauses on the guarantee and maintenance of equipment in the contract; they sell you automation without any obligation.

The absence of a service contract is not as critical as the lack of a guarantee, in the first case, the client can use the wizard to call for diagnostics, and in the second, the automation cannot be replaced free of charge even in the first year.

A lot of mistakes during the order are made by the customers themselves. For example, they decide to order automation a few years after the installation of the gate or insist on self-installation. Both errors can lead to disastrous results, since the standard conditions for the installation of equipment will not be met.

Specialists of Intbest.RF recommend ordering gates, automation and installation in a complex to guarantee the longest and most repairable service life of structures, but we are not afraid of difficulties and take on non-standard orders with no less enthusiasm.

We choose automation for sliding gates

Sliding gates are a popular entry protection for private, industrial and public areas. The drive for such a gate is simply necessary, because a heavy sash is difficult to move mechanically.

Answering the question “which automatic drive for sliding gates is better”, experts recommend paying attention to the following parameters:

- correspondence of drive characteristics and gate leaf weight (weight and traction dependence),

- climatic conditions in the region,

- type of limit switch (electromagnetic and electromechanical),

Experts insist that in conditions of Russian winters it is better to use an electromagnetic switch, since it does not have negative temperatures.

- Intensity of exploitation (for personal, general and industrial use).

Each characteristic affects the quality and durability of the gate. So, for example, traction directly depends on the weight of the sash, consider the example of Alutech engines:

- for sashes weighing up to 500 kg, the ROTEO RTO-500 model with a maximum traction force of 500 N (such a drive is used in private homes and small enterprises where the gate width does not exceed 3 meters),

- ROTEO RTO-1000 is a model with a pulling force of 700 N for gates weighing up to a ton (suitable for entrance structures in parking lots, warehouses, etc.)

- for a web weighing up to 2 tons, the ROTEO RTO-2000 model is provided (the drive is used in industrial facilities).

Russian manufacturers of automation (for example, Alutech) produce automatic drives taking into account the negative weather conditions in central Russia. A special Arctic lubricant is placed in the gearboxes, which does not freeze to -30 and guarantees uninterrupted operation of equipment even on the coldest nights. In the northern regions, the manufacturer suggests using an additional heating element, which saves the motor from frost to -60 degrees.

Sliding gates - that type of protective structure of the entrance group, which provides for the presence of an automatic drive. The door leaf mounted on one support beam is rolled to the side, that is, with mechanical control, the entire weight of the leaf is in the hands of the user.

Sliding gates can be opened manually in the event of a breakdown or power outage, but this will require physical effort.

It is worth noting that the service life of the drives is from 5 to 20 years, if you need to replace equipment, feel free to contact Intbest.RF, our experts will inspect the facility and issue their verdict on technical capabilities.

Automation for swing gates

Swing gates - a widespread construction in Russia. It is universally used to protect country cooperatives, plots, country houses, garages and parking lots. In recent years, a swinging design with an automatic drive is gaining popularity, which combines a classic design and updated functionality.

There is no definite answer to the question “automatic swing or sliding gates are better”, since a lot depends on the entry configuration (narrow and long entry groups cannot be equipped with sliding gates, and swing ones require a lot of space for the doors to move), so before making a choice, you should familiarize yourself with characteristics.

The design has undeniable advantages:

- open outward and inward,

- installed even in tight spaces,

- a budget option.

The main disadvantage is the unreliability of the pillars. Over time, they tend to bend under the weight of the sash, changing the geometry of the structure and disabling the drive.

When equipping swing gates with an automatic drive, it is necessary to consult a specialist to clarify the nuances.

- lever (operates on the principle of independent stroke of the levers and is mounted on wide columns. The opening angle increases to 120 degrees. Suitable for monolithic gates with leaf weight up to 600 kg),

- linear (at the request of the client, it is installed at the top, bottom, in the middle of the wings. Bulky posts are not required for installation of the system, which saves space. The advantage is a slowdown at the end of closing and opening, which increases the service life. The doors have an opening and closing angle of 90 degrees.)

- electromechanical (with worm gear and electric motor),

- hydraulic (used for gates with a leaf width of more than 3 m and a weight of more than 600 kg).

The underground drive option for swing gates is currently practically not used in Russia, however, is one of the leaders in the direction. The underground drive is invisible, so it does not spoil the appearance of the wings and the site itself. To protect it from corrosion, it is placed in a special box under the hinges of the wings. The operation mechanism is almost silent and allows you to open the gate up to 360 degrees. The design is designed for leaf weights up to 900 kg wide up to 5 meters.

Automation for garage doors

Having automatic gates in the garage means providing yourself comfort and convenience in rain, snow or frost. Due to the presence of automatic control, it is not necessary to install mechanical locks, locking at closing occurs automatically. In addition, lifting or rolling garage doors - reliable heat and sound insulation.

The market offers several types of automatic garage doors:

- sectional. Consist of panels connected by hinges. Materials for manufacturing are diverse. They are simple and easy to operate.

- lifting and swiveling. Go under the ceiling with a whole leaf. The movement is due to the articulated lever mechanism. They are more durable.

Drives for lifting gates vary in power, their choice depends on the weight of the gates and the width of the blade.

At present, the leading manufacturer of automation for sectional doors Alutech offers consumers drives developed on the basis of the An-Motors line called Levigato. The drives are suitable for gates ranging from 8.4 to 18.6 m 2, which in itself is a progress, because before that the drives were installed on gates with an area of up to 16 m 2 ::

- An-Motors drives are designed for a canvas with an area of up to 8.4 - 16 m 2, depending on the model,

- Marantec manufactures motors for up to 7.5 - 15 m2, depending on the series and model,

- Comunello produces equipment capable of raising the structure to an area of 8.4 - 16 m 2.

Alutech produces everything you need to automate your garage door. For its history of presence on the market, the manufacturer has established itself from the best side.

Why Intbest.RF is an excellent company choice for ordering automatic gates

Where to order automatic gates? Of course in Intbest.RF and there is not a single reason for this:

- convenient office location 5 minutes from Ugreshskaya metro station,

- 1 year manufacturer's warranty on automation

- guarantee for the door leaf - 1 year, in case of repairing the elements, the warranty is extended for another six months,

- departure of the measurer to the object at a time convenient for the client,

- cooperation with the leading manufacturer of gates and automation Alutech.

Intbest.RF is not just a supplier of equipment or a gate installation company. We truly care about our customers and provide a range of services for the selection, manufacture, delivery and installation of equipment. If you were tormented by the question “which automatic gates are better and where to order them” - you have found the answer.

Highlights when choosing a drive

Any experienced and successful person can tell you without any problems that the details play a crucial role. If you look at the photo of the drive for sliding gates of different manufacturers, it will be quite difficult to find significant differences. This is because they are hidden inside the device, and therefore can change the characteristics of the device.

The drive for sliding gates must be selected for power, because the gates themselves are very difficult, climatic conditions and cost.

If you wish, you can find other features, such as the presence of power from the network or battery, but we are not interested in it now.

With power, everything should be very clear - the heavier the gate, the more powerful the drive device for sliding gates should be, but even here there are pitfalls.

Regarding the weather, both precipitation and the general temperature regime in your region are important here. The thing is that some models may experience certain problems in a climate like ours, where in winter in some cities the temperature can drop 30-40 degrees below zero.

First of all, temperatures affect the main chains and mechanisms, which is why certain models released in other countries sometimes do not work very well in our climate.

A similar situation is with heat, but its influence is not so great, because overheating should not happen anyway, since the mechanism does not work constantly.

Other features that we have already noted, most often appear as a bonus, and therefore are not considered mandatory. Next, I would like to consider the points we mentioned in more detail.

Manufacturer country

Now in the market you can often find drives for sliding gates from several countries - domestic, Chinese, Italian and German.

We have identified just four countries because the vast majority of products are produced in them. Naturally, there are other suppliers, but their share is much smaller.

Among the Italian manufacturers can distinguish Came. They have fairly high-quality products, which are popular in the CIS countries - although it has its own characteristics, it copes very well with a difficult climate.

On the other hand, there is Doorhan - a domestic manufacturer whose products are ideally suited for a frosty climate.

If we talk about the price, then domestic drives are sold on average for about 10 thousand rubles, while for a foreign analog you sometimes have to pay almost three times as much.