Creating a floor surface is an important and responsible process that requires a careful approach to the nuances. Most often, a specially poured composition with a small coating thickness is used to align and correct minor flaws.

The price of such a material is quite high, so the correct calculation of the consumption of bulk floor per 1 square. m makes it possible to determine the required amount.

Conditions Affecting Consumption

The consumption of bulk floor per 1 m2 is influenced by many factors that must be taken into account to obtain an objective calculation.

So, the following conditions are distinguished:

- The correctness of the preparation of the foundation. This stage includes a number of mandatory procedures. Firstly, cracks and cracks are smeared, which eliminates the overrun per square meter of approximately 20 to 40% of the mixture, depending on the defects.

Then a primer is applied in at least two layers. The composition is selected with the effect of deep penetration, this allows you to fill in numerous pores, which can take up to 10% of the filled solution. - Self-leveling floors are used to level coatings that have minor flaws. The layer recommended for filling is up to 5–8 mm. Although there are compounds that can successfully create coatings up to 90-100 mm thick. But still, with more significant deformations, a suitable version of the leveling screed is preliminarily arranged.

- The area of the room and the thickness of the desired coating.

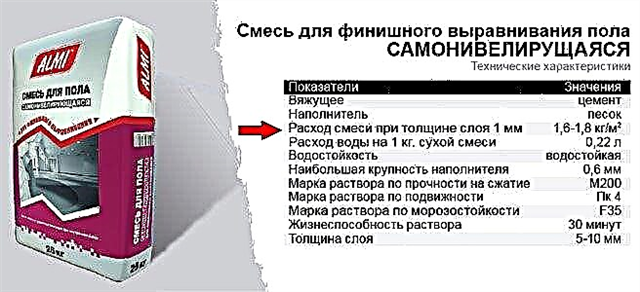

- The density of the material used. The indicative data are as follows:

- polyurethane compositions - from 1.25 to 1.35 kg / l,

- materials based on epoxy resins - from 1.35 to 1.5 kg / l,

- acrylic cement mortars - 1.6 kg / l.

- Indicators of temperature and humidity. It is advisable to comply with the parameters recommended by the manufacturers.

Thus, the correct consideration of these factors makes it possible to avoid errors and more accurately calculate the consumption of bulk floors.

Flow rate calculation

How to calculate the bulk floor? Initially, the volume in cubic meters is determined. The fact is that indicators expressed in m² are not very suitable for obtaining data on coatings, which also include thickness.

- It is necessary to calculate the area of the room in which the coating will be poured. This show is obtained by multiplying the length by the width. If the room has complex geometry, then you can divide it into sections and calculate the total area in parts. But it is much better to use the technical plan of the house.

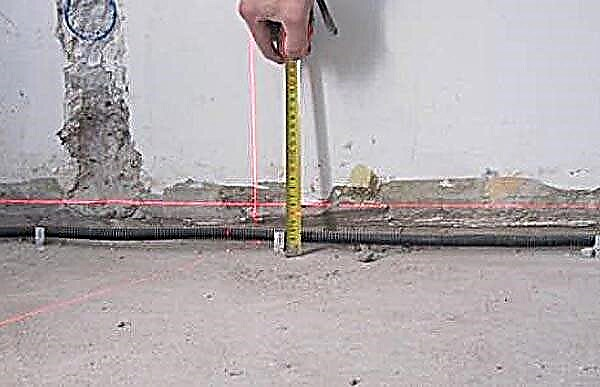

- Using the level, the required thickness is determined. When working on surfaces with severe curvature, the water level is used. To clarify minor deviations, a standard or laser level is used.

- The resulting parameters are recorded on the sheet. It is advisable to check them.

To calculate the consumption of the bulk floor, it is necessary to determine the thickness of the future screed

To calculate the consumption of the bulk floor, it is necessary to determine the thickness of the future screedApproximate consumption of bulk floor per 1m2:

Let's say the length of the room is 4 m and the width is 5 m.

The thickness of the poured layer is 3 mm. Many manufacturers indicate that 1.5 kg of compound is required to fill 1 mm.

3 * 1.5 = 4.5 kg per m2.

That is, one kg with a layer thickness of 3 mm will require 4.5 kg of dry mix. Then the consumption of the bulk floor per 20 square meters will be 90 kg.

Next, you need to evaluate the density of the product. Please note that this parameter is approximate. To obtain more accurate indicators, you should focus on a specific manufacturer. An online calculator helps simplify the procedure.

The consumption of the mixture depends on its density and differs among different manufacturers.

The consumption of the mixture depends on its density and differs among different manufacturers.

The calculation of the number of polymer compositions is carried out by a similar method. The main thing is to use values greater than those specified by the manufacturer in the technical parameters based on a thickness of 1 mm per m2.

Consumption reduction

The calculation of the bulk floor shows that a significant amount of the mixture will be required for operation, but it is also necessary to provide for the consumption of related materials. The total cost of all products used can be quite large.

To reduce consumption, you can use the following tips:

- When working with polymer bulk coatings, many craftsmen use the underlying layer. This is a fairly common trick, it is created after filling the base base. To do this, quartz sand is poured onto a surface that has not yet set, and after drying, the excess is removed. Then the main composition is poured, the consumption of which is greatly reduced.

- The filling procedure and subsequent leveling is carried out using special tools. They are not difficult to handle and accessible to everyone, they allow faster and better distribution of the material on the surface.

- Select a trusted manufacturer. The fact is that the popularity of such solutions is steadily growing, this leads to the appearance of low-quality products on the construction market. For example, unscrupulous manufacturers add much more weighting additives to the mixture, which significantly increases the consumption per square meter. However, not all reflect such data on the label.

How to calculate the right amount of bulk floor? For this, a fairly simple scheme is used, as well as data that each manufacturer indicates for his material.

Thin-layer bulk epoxy coating - 0.8-1.2 mm thick

- Material and consumption: EP-0302-0.25 kg / m2, EP-2331 - 1.4 kg / m2, 0104 - 0.5 kg / m2.

- Price of material price: 123.75 + 518 + 4.5 = 646.25 rub./ m2.

- Material price with 10% discount: 581 rub / m2.

- The main types of work: grinding, primer 2 layers, painting 2 layer.

- Prices of work: from 200 m2 - 500 r / m2.

- Price materials (discounted)

+ work (minimum cost): 781 rub

Thin-layer bulk polyurethane coating - 0.8-1.2 mm

- Material and consumption: PU-0310 - 0.4 kg / m2, PU-2340 - 1.6 kg / m2.

- Price of materials price: 124 + 568 = 692 rub./ m2.

- Price of materials with a 10% discount: 622 rub / m2

- The main types of work: sanding, primer 2 layers, pour the floor.

- Prices of work: from 200 - 500 r / m2.

- Material price (discounted)

+ work (minimum cost): 822 rub

Epoxy bulk coating - 1.8-2.2 mm

- Material and costs: EP-0302-0.3 kg / m2, EP-2331 - 1.9 kg / m2, 0104 - 2 kg / m2.

- Price of materials price: 148.5 + 703 + 18 = 869.5 rub./ m2.

- Price of materials with a 10% discount: 782 rub / m2

- The main types of work: sanding, primer 2 layers, pour the floor.

- Prices of work: from 200 - 500 r / m2.

- Material price (discounted)

+ work (minimum cost): 982 rub.

Polyurethane bulk coating - 1.8-2.2 mm.

- Material and cost:PU 0310 0.4 kg / m2, PU 2340 - 2.2 kg / m2, 0104 1.4 kg / m2

- Price of materials price: 124 + 18 + 710 = 852 rub./ m2.

- Price of materials with a 10% discount: 766 rub / m2

- The main types of work:sanding, primer 2 layers, pour the floor.

- Prices of work: from 200 - 500 r / m2.

- Material price (discounted)

+ work (minimum cost): 966 rub

Epoxy smooth thick-layer coating with a reinforced layer - 3.5-4 mm.

- Materials and expenses: EP-0302-0.25 kg / m2, EP-2321 - 1.4 kg / m2 ,, 0104 - 4 kg / m2 (powder), EP-2331 - 0.6 kg / m2, EP- 2331 - 1.5 kg./m2

- Price of materials price: 123.75 + 442.4 + 36 + 222 + 555 = 1279.15 rub./ m2.

- Price of materials with a 10% discount: 1151 rub / m2

- The main types of work: sanding, primer with 3 layers, 3rd layer with sand, sealing, pour the floor.

- Prices of work: from 250 - 500 r / m2.

- Material price (discounted)

+ work (minimum price): 1451 rub.

Obvious benefits for business projects

If you are a business owner, you probably already calculated the costs, but given the relevance of the question, you are interested to know - are there discounts or at least counter offers from the manufacturer with which you can reduce the cost of calculation? When buying domestic polymer compositions manufactured under the Polytek brand, you can take advantage of a unique offer - the purchase of high-quality materials (solution in convenient packaging) in combination with professional furnishing services.

This is a significant savings., since complex solutions are always cheaper, and given the improved quality of materials and the expert skill of our company’s specialists, you can easily become the owner of a very profitable option, implemented to the highest standards. Such work performed by third-party contractors is always more expensive, and if you take the elite quality of materials, the amount may well double, and sometimes even triple. That is why it is optimal to take advantage of the manufacturer’s offer - the purchase of bulk floors + pouring services.

Industrial floors

Starting work projects large area important before carry out an expert assessment of all surfaces in order to identify the main flaws and correctly determine the functionality of each zone. Depending on the information received, it is possible to obtain an approximate consumption of polymer cement-sand mixture for leveling + finish layer. However, for the full picture, it is necessary to list all the stages of work and materials used during their implementation. It:

- Substrate preparation (leveling with a concrete screed or using a self-leveling compound).

- If the screed is already there - surface repair (repair of cracks, indentations).

- Primer by impregnation of deep penetration.

To cut consumption of the bulk floor, it is important not only to repair the entire floor surface, but also to align the horizontal plane well to the ideal level. When arranging industrial floors, this is a weighty argument, because a difference of 1 mm to a length of 10 meters can additionally add a few kilograms of an expensive mixture, which in turn significantly affects the overall cost.

Another important question - zoning of industrial flooring. By creating a map of zones with different functional loads, you can choose several different compositions, each of which will be able to perform the main function, without compromising the quality of the coating. For example: in the zone of the entrance or entrance group, the floor carries maximum loads, especially in cases when loading equipment moves in addition to production workers in this territory. In this period, it is important to use such a quality composition that is able to withstand such loads.

If it is possible, it is better to pre-use the filling of a highly filled mortar with reinforcement, and polyurethane self-leveling floors are perfect for the finish layer. In areas with minimal load, simply epoxy paint coatings can be used. These mixtures have excellent strength, low consumption and low price. By composing the total area of a separate functional zone, you can calculate the consumption of the mixture per 1 m2 for each selected material.

Surface priming

Although it seems to us that priming is an insignificant procedure, it is it that reduces the consumption of expensive bulk compositions. The fact is that the impregnation creates not only optimal conditions for adhesion, but also small holes and pores remaining after repair will be hidden. If this technology is violated, then the rate of consumption of the polymer composition can increase about 500-600 grams per square meter, which in the final summation will be very significant indicators. For this reason, it is better to pass the entire floor surface not once, but more, two or three.

How to calculate the amount of mixture for a bulk floor per 1 m2 with a layer thickness of 1, 2, 3, 5 MM?

To implement an approximate calculation of the consumption of the bulk floor (finishing materials), it is necessary to completely finish all the preparatory work. Given the high cost of polymer compositions, it is possible to carry out preliminary measurements and derive the average value, based on the difference in deviation from the horizon. To do this, use the laser level along each wall. From zero to the opposite mark there should not be a difference, but if there is one, add at least 1 mm to the maximum height and you will get the thickness of the working layer. Taking a calculator and adding up all the indicators, then dividing them by 4, you will get an increase in the recommended layer thickness.

To find out how much materials are needed for the entire room, you can use the following formula: SхHхP = V, where

- S is the total area of the room,

- H is the thickness of the fill layer (recommended + drop),

- P is the density of the emulsion (indicate manufacturers on containers with a liquid composition),

- V - material consumption per square meter of the base.

This is a simple formula., which is applied to single-layer finishing floors, therefore, in multilayer bulk systems, the flow rate is calculated taking into account each layer. Before starting work, it is worthwhile to carefully study the manufacturer's recommendations on mixing the compositions (watch the video), since the slightest non-compliance can lead to a decrease in density and uneven drying of the material. This indicator can affect not only the average component of the flow, but also on the aesthetic appearance of the surface. Indeed, the lower the density of the mixture, the bulk floor can shrink and provoke, thus, its deformation and cracks in the coating. It is also important to remember that this formula cannot be universal, since polyurethane, epoxy or quick-hardening mixtures are materials with different densities.

If you do not want to allow an overrun of the amount of expensive polymer blends, the best option for you is comprehensive services from the Polytech company. When performing work on a large area, we will go to the facility for free, study in detail the features of all floor surfaces, give important recommendations for reducing consumption when pouring each of the coatings, and proceed with the project. For industrial floors, our warranty is 10 years or more, so you can be assured of the quality of our work! Contact numbers are indicated on our website. Waiting for you!

We are ready to offer you device (installation) of the bulk floor in any room. Our materials on a polymer basis can be poured in any room, as they contain additives giving them decorative (for example, colored - tinted according to the RAL color chart, transparent to the picture, linoleum, marble) properties and even other components giving them wear resistance - repair will not be needed for long. For self-application, it is better to see photos and videos on this subject.

Perfect base in order to fill the coating is a material such as concrete (or should be such as a concrete floor or cement screed). The thickness of the coating is variable and very much depends on what basis it will be poured. Calculation can be done by our employees, call our online store and we will tell you the price of materials and the cost of work for your area. Through the form "order calculation" you can ask a question, write a comment - share your opinion and cancel the answer, do not forget, please indicate your name, e-mail, and phone. All products are in stock, there is delivery.

Information

The online calculator for calculating the bulk floor is an indispensable assistant that will be useful to an experienced master and a beginner in the construction business will need it. Thanks to this tool, competently calculating the consumption of bulk floor per 1m2 will not be any difficulty. Of course, the calculation of the bulk floor can be done in the old fashioned way, on paper, using a bunch of formulas from various reference books, however, it will take a lot of time, you will spend time on the calculation, instead of just entering the necessary parameters into the bulk floor calculator and finish begun business.

It is with the help of this tool that you can save time, nerves and strength, instantly get parameters such as:

- room area

- the required volume of the mixture

- the cost of acquiring the mixture,

Room dimensions

Well, when we have the simplest possible room - rectangular. Then you just need to measure the two sides of the room and enter them in the parameters of the calculator. And what to do when the room has a shape different from the rectangle? - Firstly, do not rush to close the calculator, all that is required of us is just to divide the room into the required number of parts and calculate for each individual site, and then summarize the finished indicators.

Screed Dimension Option

- Screed thickness N,

- The height of the angle And

- The height of the angle,

- The height of the angle C

- The height of the angle D.

In the parameter “Screed thickness H” it is necessary to indicate a number indicating the thickness of the bulk floor. The calculation of the thickness of the bulk floor is as follows: the angle height parameter is selected for which the deviation from the “zero point” is minimal, or equal to zero and the previously entered parameter “Screed thickness H” is added to it. The height of this angle will be the point from which the elevation difference at the other angles will be considered. Thanks to this approach, the maximum accuracy of all calculations is achieved.

Mix, and calculation types

- on packing

- by name.

If you consider the mixture by packaging, then you must specify several parameters, namely the weight of one bag and the price for one bag. Pressing the button “Calculate” - we get the required number of bags of the mixture to carry out the work, as well as the exact number of material costs for their purchase.

If you consider the mixture by name, you must select one of the manufacturers of the mixture that is suitable for you from the list provided, and specify the price parameter for one bag. In this case, the weight of the bag is indicated in the list next to the name and you do not need to enter a separate item. In the same way as in the first version, as a result, you get the necessary number of bags of the mixture to carry out the work, as well as the exact number of material costs for their purchase.