A great influence on the performance properties of the parquet board is provided by the wood species from which the front layer is made. Larch parquet board has many positive characteristics, thanks to which it provides not only a beautiful appearance, but also the durability of such a coating.

Larch - a quality and popular material used for flooring

The main advantages of larch

The large distribution of larch as a high-quality material for the facing layer of parquet boards is not at all accidental. Its use is due to the following characteristics:

- Resistance to water, high humidity. Parquet boards made of solid larch perfectly resist deformation and warping even in a humid environment, which greatly expands the possibilities of using this material.

- Excellent resistance to decay and resists the growth of bacteria due to the presence of gum in the wood. In addition, the fungus does not take root on the surface of the larch. Also, larch perfectly maintains the indoor microclimate.

- The hardness of the rock can withstand significant physical exertion. In addition, the larch surface acquires even greater strength over time. The use of brushing will further increase the hardness of the coating.

- The price range of a larch parquet board is significantly lower than that of other breeds with similar characteristics.

- A wide variety of shades and textures. Depending on the growing conditions, age and place from which the wood is cut, larch can have several different shades and differ in texture.

- The larch surface resists UV exposure. Accordingly, the surface color always remains saturated, does not fade.

- The massive larch parquet board has excellent thermal insulation characteristics and retains heat in the room. On such a surface you can walk barefoot even in winter.

Larch coating is relatively cheap but also angry

Deficiencies and limitations in the use of larch

Each species of wood has its own advantages and disadvantages, imposing restrictions on their use. Like any material, larch also has disadvantages:

- surface care from larch is undesirable with the use of aggressive chemicals,

- under the influence of heavy furniture with sharp legs, dents may appear on the surface,

- in places devoid of varnish protection, delamination of the surface is possible, which will lead to the formation of splinters,

- the complexity of applying impregnation and coloring compounds associated with high resinous wood.

Before using the material, it is reasonable to study all its advantages and disadvantages in order to take good care of it in the future.

All the disadvantages of larch are associated with the structural features of wood. Porosity leads to delamination of the surface, absorption of detergents, which somewhat limits the possibility of using chemistry to clean the unprocessed floor. However, simply coating the surface with varnish will solve this problem.

In addition, the surface damaged as a result of careless handling can be looped, sanded and varnished again, which completely restores the decorative qualities of the material.

Larch application possibilities

A large number of resins contained in larch wood allows it to be used to cover the floor even in places such as the bathroom, sauna. Unlike most other types of wood, larch in these rooms feels great and gains even greater hardness over time.

The porous structure not only allows the tree to breathe, but also creates a microclimate in the room. Washing the floor with a wet rag will allow it to absorb part of the moisture and subsequently, gradually evaporating, a comfortable atmosphere will be created in the room.

If you need to lay an inexpensive parquet in the bathroom - you can turn your attention to larch

Larch perfectly resists significant temperature changes, which allows it to be used in unheated rooms, summer verandas, in summer cottages. It is advisable that before a significant decrease in temperature the board was dry, this will preserve the integrity of the coating after warming.

Unlike other conifers, larch has much greater hardness and wear resistance, which was used by our ancestors. The most valuable breed is considered to be Siberian, which is significantly superior to other species in all respects.

Features and Benefits

A board from an array of larch has a number of undoubted advantages, among which one can note:

- Long life of this tree. With proper care, the coating will retain all its characteristics and beauty for more than one decade after installation.

- Safety and hypoallergenicity. Larch is the best choice for decorating rooms in which allergy sufferers live. This massif of a tree is almost not subject to decay, the formation of fungi, the multiplication of dangerous bacteria and microorganisms - thanks to the gum in the composition.

- Improving properties, maintaining the indoor climate. Larch contains substances that help prevent colds and have a positive effect on the nervous system. This property of the material is preserved for years after its installation.

- Increased resistance to moisture - thanks to the special structure of the dies made of solid larch.

- Good tolerance of temperature fluctuations.

- Rock hardness. This property allows the floor to withstand severe physical stress and over time even increases the strength of the coating. Brushing allows you to further increase hardness.

- Beautiful and expressive structure, perfectly visible in the context. From the base to the bark, the wood is decorated with perennial dark rings that stand out against the background of a lighter array. Such a parquet floor is able to qualitatively transform any interior.

This coating differs from similar materials in larger sizes. Laying boards is similar to the technique of installing a laminate: a chessboard, a run-up or a diagonal. The increased dimensions also affect the price of the slats - they are more expensive than similar products made from another array.

Classification

Parquet boards from solid larch are of various types: single-lane, two-and three-lane. Products are also classified by grade. Highest (number 0) is distinguished by the highest quality of boards, uniformity and softness of the picture, lack of knots. On products of the first grade, up to 30% of defects and the presence of small knots are allowed. On the second-grade board, defects are evenly dispersed over the entire surface. Parquet planks of the third grade have a large number of aesthetic defects.

Preparing the foundation before laying

Installation of boards is carried out on an aligned solid base. The best option is a concrete screed. Logging is not allowed. The permissible indicator of unevenness of the base is 2 mm per 2 m. It is also important to verify the dryness of the concrete screed. The temperature of the surrounding space in the room where the installation of the parquet coating is carried out should be in the range from 15 to 23 degrees Celsius, the humidity level should be from 40 to 60%. Foamed polyethylene should be placed on the concrete floor to provide better sound and waterproofing.

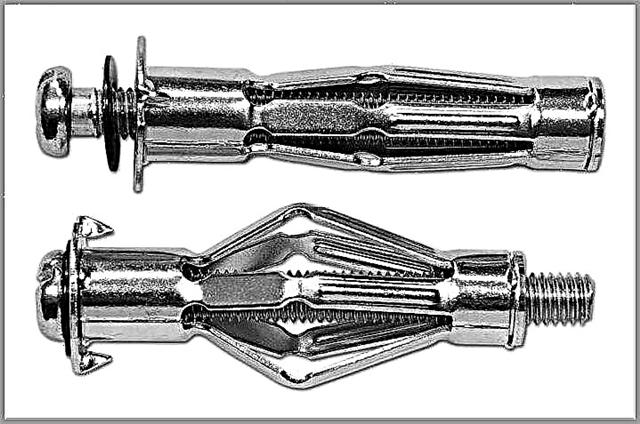

Laying on the floor can also be done without using a substrate - after preliminary priming the base and gluing plywood 12-20 mm thick to it, cut into 75x75 cm squares. At the same time, the plywood should be laid out so that the ends butt together. The amount of thermal play between the plywood sheets should be between 8-15 mm. Recommended gap between wall and mdash plywood, approx. 20 mm. Sheets are fastened in the direction from the center to the concrete base with dowels, nails, the distance between the fasteners is 25-35 cm. At the end, grinding is performed to exclude differences in the height of sheets located next to each other.

Laying a parquet board - stages and features

Before laying out, the mounted board must be unpacked and left in the room for acclimatization. Do not allow the placement of dies from the array near the heating appliances or keep them in a room with humid or dry air. This will not only negatively affect the efficiency of parquet work, but will also cause a quick damage to the coating. It is important to comply with each styling feature and carefully perform all the steps:

- Layout of the first row of slats with a groove to the wall - with a gap of 10-15 mm (using wedges). It is recommended to use larch of different lengths and alternate dice randomly.

- Application of special glue to plywood.

- Installation of parquet dies. Each plank must be additionally pulled to the plywood with self-tapping screws screwed into the crest of the plank at an angle of 45 degrees - the groove of each next plank should cover the previous mounting location. The distance between the fasteners is 30-40 cm. The end of the plank is attracted by self-tapping screws with self-drilling heads and self-heating hats to prevent possible damage to the coating. In the case of using standard self-tapping screws, you must first drill and countersink the material.

- Finishing sanding the array and coating it with varnish, oil, special wax.

Scope of application

To issue an array of larch, you can premises for various purposes. High performance characteristics of the material allow it to be used in residential buildings and public places, which are characterized by a large load - these are public halls, reception rooms, gyms, offices.

A high-quality board can be made out not only of internal spaces, but also of arbors, balconies, verandas in the absence of strong temperature extremes. For use in damp rooms, the trims are treated with a mixture of resin, oil and wax, and to change the color, they are varnished. If it is necessary to obtain a natural woody shade, oil is used for surface treatment - the dies become dull.

Product Features

To begin, consider the main parameters that all products of this group have:

| Production material | Larch massif, there are no glued layers in the product, elements are cut from solid blanks |

| Plank thickness | Most often, the figure is 19 mm, but the value may differ upwards. |

| Width | Depending on the collection, it ranges from 85 to 160 mm; this is the final size excluding the comb |

| Length | Varies from 900 mm to 2000 mm |

| Material moisture | No more than 8% |

| Connection system | Spike groove |

Advice!

It is best to purchase a massive parquet board, which is produced by the method of radial sawing, which differs in that the wood blooms not in one direction, but at an angle to the core, so that the fibers go along the elements and the deformation coefficient of the finished products is much lower.

Radial (2) differs from the usual tangential cut, marked with the number 1, in that the fibers are located along the board, which allows the material not to deform under moisture drops, and the board is twice as durable

The advantages of this type of coating

Several key factors should be highlighted here:

- Larch is well known for its positive characteristics: high resistance to moisture and pests, wear resistance of the surface and long service life, you can find floors made of such material that were laid in the 18-19 century,

- The structure of wood is very attractive, and the texture of each element will be unique and inimitable, unlike the same laminate in which the pattern is duplicated. Using special coatings, you can give the surface a certain shade, which will even more profitably emphasize the beauty of natural material,

- The price of products does not apply to the budget segment, but if you compare this solution with options of comparable quality, you can make sure that a massive parquet board is the most affordable option in this segment,

- Unlike laminate, glued boards and other constituent elements, there are no glue and other foreign compounds in the composition of the products. This makes this option as environmentally friendly as possible and allows it to be used in rooms of any purpose - from public halls to children's rooms,

- The processing process is that you need to remove all contaminants from the surface and apply a protective composition, most often it is a special wear-resistant varnish that provides excellent protection against moisture and abrasion resistance,

A well-crafted coating will retain an attractive look for much longer

- The spike-groove connection system allows you to combine elements as tightly and efficiently as possible, which allows you to perfectly lay the coating even for those who have no experience in carrying out such work. Lock joints make the process much easier

It is important that the locks are cut as accurately as possible, so the quality of the fit of the elements depends on this

- The material has high thermal insulation properties, which are much higher than that of the popular laminate,

- Another important advantage is the maintainability of the surface, if scratches and damage appear on the material over time, then the floor can be sanded, after which a new coat of varnish is applied to the surface.

Styling process

When doing the work yourself, you should be guided by several recommendations, and the installation instructions are as follows:

- First of all, it is necessary to level the base, if there is significant damage or surface drops, then they must be repaired, cement mortar is suitable for screed, and sheet materials are used for wooden flooring,

- In order to improve sound insulation and reduce heat loss, it is necessary to cover the sound insulation first, and then the sheet insulation. This will ensure the best performance characteristics of finished structures,

Important!

To simplify the work, you can use an option such as foamed polyethylene, it performs both functions at once - and protects against moisture penetration, and has soundproofing properties.

Foamed material can solve several problems at once

- Next, it is necessary to cover the surface with wooden plywood 20 mm thick, it will serve, firstly, as a reliable base, and secondly, it will further increase sound absorption. Also, plywood will serve as the basis to which the finish layer will be attached,

On wooden floors, heat and sound insulation are not required.

- Laying the parquet board is carried out from one of the walls, deformation gaps of 5-10 mm are necessarily left, each of the elements is first put on a special glue, after which it is additionally fixed with screws that are screwed into the spike. It is better to use special fasteners so as not to split the material during operation,

- The parquet board is laid apart, that is, the joints in adjacent rows should not coincide, this, firstly, will increase the reliability of the floor, and secondly, improve the appearance of the surface.

Pros and cons of larch parquet

This wood is resistant to sudden changes in temperature. It practically does not deform. The service life of such a coating can reach several centuries. Nowadays, you can find rooms that were built in the 18-19 centuries and it is noteworthy that the floor in them is covered with a larch parquet board.

An example of such a coating in the interior

Unlike artificial parquet, the drawing of each detail is unique. The price is affordable. Considering that larch wood is considered an elite material, its prices are very affordable and there is a wide range. Therefore, anyone who wishes will pick up an option for themselves afford.

Due to the fact that this coating is made of solid wood and does not use glue, it is environmentally friendly, it can be used in rooms for children.

Larch parquet board is very easy to repair, does not require large expenses for restoration. It is easier to grind such parquet, the top layer of the coating is easily removed, and deformed or broken parts can be easily restored or replaced with new ones.

How is grinding such a board done?

It is easy to pick up new parts for repair, due to the fact that the drawing on them is natural. Due to the naturalness of the material, a larch parquet board looks beautiful, expensive and cozy.

With all its advantages, such parquet has its drawbacks:

- Intolerance to high humidity. To use such a coating in rooms with old windows or poorly heated is fraught. With a sharp increase in humidity, the joints between the elements may slightly diverge. Boards may succumb to slight deformation.

- Larch tends to form small delaminations, resulting in splinters may appear.

- The experience of people who have chosen this type of coating says that furniture on thin curly legsespecially heavy (such as a closet) may leave small dents.

Having gathered all these shortcomings together, we can conclude that they are very superficial and can be easily eliminated with the help of properly selected varnish or wax for opening wooden floors. As for humidity, modern windows will fix everything here.

Larch floorboard prices

You can buy a larch parquet board in Moscow through the Internet, or in specialized stores.

Calculators on the same sites allow you to compare prices and buy a larch board. Feel free to use them, do not hesitate to ask the consultants of these stores your questions. They get paid for it.

Prices for larch parquet depend on the level of raw materials, the manufacturer’s company, the “birthplace” of wood and the place of purchase. After all, each site and store has its own suppliers. Wood is used alone, but the places for growing the tree are different, and this is the cost of delivery of raw materials.

On average, in the market (at the time of writing: spring 2016), the price ranges from 1,000 rubles to 100,000 rubles per square meter. The price range is great and you can choose a quality parquet that will satisfy your wishes and will be affordable for you.

Video with tips on laying larch parquet, see below.

Nice repair! We will be grateful if you share the article on social networks with your friends.