Wood is a valuable material that is widely used in construction, in the manufacture of interior items, interior partitions, for flooring. Its biggest advantage is environmental safety, durability, noble appearance. To preserve, improve aesthetic characteristics, as well as to extend the life of the tree, a special colorless or colored varnish is used, which allows you to reliably protect the base from the influence of any adverse factors.

The properties

Varnishes have a viscous consistency. They include polymers, resins, a solvent, which after application forms a dense protective film, additional components that accelerate the drying time. Depending on the type and amount of solvent, the substances have a different smell, color, and drying time. So, alcohol-based varnishes belong to quick-drying compositions. Drying time can be 20 minutes. Slow-drying water or oil based varnishes harden within 6 days.

After applying the paint material, a glossy glossy surface with a high reflectivity or a matte surface with a low reflectivity may form. There are also compositions that form an intermediate version, which occupies a middle position between gloss and dullness. The floor covered with such material looks updated.

A distinctive feature of protective coatings is the unique ability to preserve the natural beauty of wood.

Appointment

Varnishing wooden substrates is necessary to protect them from moisture. Wood easily absorbs liquid, resulting in not only deteriorating the appearance of the material, but also there is a risk of mold, fungal damage to the surface. The varnish coating prevents the appearance, reproduction of insects that harm the wood. Fire retardant paints and varnishes protect the tree from mechanical damage, exposure to adverse weather conditions. The varnish makes the base smooth, even, safe.

Thanks to this material, you can emphasize the original wooden ornament, make the surface updated, bright, saturated with color, brilliance. Lacquer coating allows you to create a harmonious atmosphere of comfort indoors. It also serves as an indisputable decoration of street structures. Paint and varnish substance is used to cover any wooden surfaces: floor, furniture, partitions, fences, any facade products. To obtain a quality base, an appropriate composition is selected.

Types of compounds

Depending on the constituent components, types of paints are distinguished.

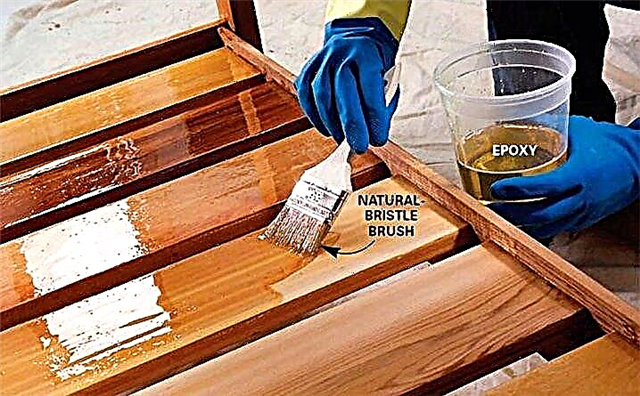

- Epoxy. The composition has high strength, hardness, moisture resistance. It dries quickly. It is used both for external, and for internal works.

- Polyurethane. Universal composition suitable for external use. The varnish has high strength, hardness, adhesion (adhesion to the surface). It is used to cover floors, decks on a yacht, furniture, any items made of wood.

- Oily. The composition has high hardness, strength, moisture resistance. It dries for a long time. It is applied to internal works.

- Alkyd. It has wear resistance, fire resistance, long service life. It has an unpleasant odor. The composition is used for flooring.

- Water Based Acrylic Varnish. Environmentally friendly composition, practically odorless. It dries for a long time. It has fire retardant properties, preserves the original wood ornament. Has not very high wear resistance, moisture resistance.

- Cellulose Nitrate Varnish. The composition dries quickly, has medium strength, has an unpleasant odor. It is applied to any internal works, except a floor covering.

Manufacturers

Among foreign and domestic manufacturers, the most popular brands can be distinguished.

- Technocolor. The products of the domestic company have an environmentally friendly composition. The material can be used in the children's bedroom. For production, modern equipment is used to create high-quality paints and varnishes. The product line is represented by a wide range of varnishes for coating wood of any species.

- Dulux. Products of the English manufacturer are of high quality, wear resistance, quick drying. After hardening, the surface acquires an elegant appearance. Varnishes are used to cover any wooden products. They perfectly protect the surface from negative external influences, moisture, ultraviolet radiation.

In order to give preference to a particular manufacturer, first of all, you should carefully study the characteristics of the composition, purpose, basic characteristics of the varnish.

Application rules

Before applying the substance, it is necessary to carry out preparatory work to prepare the base. The wooden surface is leveled by grinding, all cracks are closed. After cleaning the base from dust and dirt, the painting process is started.

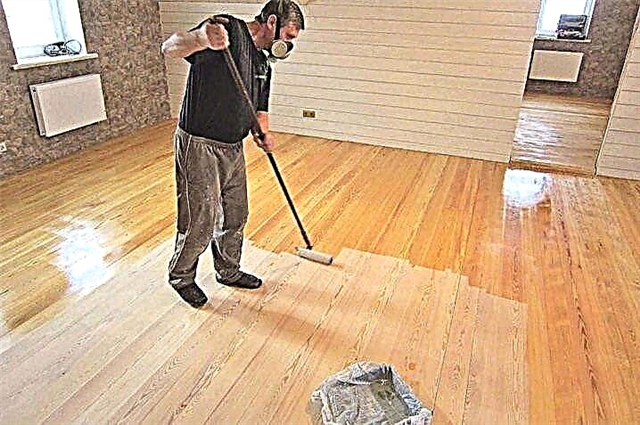

Varnish is applied with special devices. For this, a brush, spray gun, spray or roller can be used. The number of layers applied depends on the hardness of the wood. Soft coats may require up to four layers of material. When varnishing harder rocks can be limited to two layers.

The consumption of paintwork depends on the quality of the substrate. In the presence of a large number of deep pores, bumps will need more substance. The thicker the composition, the greater its quantity will be required. Therefore, varnish is often diluted with special formulations or water. When applying the composition with a brush or roller, the consumption of the substance is greater than when working with a spray gun.

To achieve the best result, all work is recommended to be done at an ambient temperature of 19-20 degrees. The humidity should be about 50 percent.

How to choose

When choosing a paint and varnish material, it is necessary to take into account the properties of wood, operating conditions. Depending on what kind of work the varnish is intended for, for the work inside the house or outside choose the types of compositions. For example, to coat the floor with varnish it is recommended to choose a clear, odorless varnish. For painting products on the street, compositions that are resistant to temperature extremes, frost, high temperature, and high humidity are suitable. The presence in the composition of additional components that effectively fight bacteria, insects, will protect the material from the damaging effects of rotting, destruction.

It is important to consider the moment that after applying varnish the color of the wood changes. It may become lighter or darker. When choosing a varnish for coating indoor surfaces, attention should be paid to the presence or absence of odor, chemical impurities that evaporate harmful substances. For example, when decorating a children's room, a flame-retardant, transparent, odorless varnish is suitable. These properties are possessed by a polyurethane or acrylic composition based on water. The right choice will provide the desired result.

You will learn about the methods of processing wooden surfaces from the following video.

Features of varnishes for wood

The industry offers customers several types of varnishes, so they need to be considered in more detail:

| Oil |

|

| Alkyd | For the manufacture of synthetic resins. It happens that they are called oily, since synthetic oils are the solvent, but the characteristics of the product are an order of magnitude higher than the previous ones. Use the product indoors. |

| Alcohol |

|

| Nitrocellulose | Allows you to create a very durable film on the surface. Apply indoors. |

| Polyester |

|

| Acrylic |

|

| Polyurethane |

|

Alkyd glossy colorless varnish for wood for interior work PF-283

Tip: when using water-based polyurethane varnish, we recommend adding reinforcing additives to its composition in order to significantly increase its service life.

How to choose a varnish for wood processing

Here are some things to consider:

- What characteristics should the treated surface receive?

- Do you have the skill and experience in applying coatings?

- Where you plan to use or for which product the product is intended.

- What is your finishing budget?

Colorless polyurethane varnish for wood application

Usually the choice depends on personal preference.

- Water-based varnish is more chosen by those who care about environmental safety - it practically does not smell and does not affect our health, so it can be safely used for decorative work in a children's room. At the same time, professional furniture makers ignore it, because after it the surface becomes dull.

- Alkyd varnishes are easy to use and their price is affordable for many, so beginners often use them, since the product is easy to remove with white spirit in case of an error.

Alkyd-urethane wear-resistant colorless floor varnish

- Professionals usually use polyurethane varnishes. They are durable and can create a durable film on the surface. For their application, a spray is most often used.

We must not forget that even transparent varnish can give the wood a yellowish tint. In addition, each type has its own application technology, after which it is necessary to accurately withstand the drying period.

One-component clearcoat for wood for outdoor use

Water based varnish

They have an acrylic or polyurethane base, which is why they are excellent for processing wood indoors. They can be one-component and two-component (see also the article “Oil paint on wood - everything you need to know about this group of compounds”).

Belinka two-component clearcoat for water-based parquet

The first are not too durable and their life is short, but they are easy to use. The second consists of a base and hardener, they are able to provide better protection. Safety and environmental friendliness of the product is associated with the absence of toxic solvents in their composition.

The average consumption of the material depends on its brand and the desired layer thickness.

Usually 1 kg of varnish can be coated if the wood:

- planed - 15-17 square meters. m

- sawn - 5-7 sq.m.

In the photo - colorless varnish allows you to preserve the texture and beauty of wood

Benefits

- Environmental cleanliness - they do not have solvents and toxic materials in their composition, therefore they can be safely used for interior work, including in children's rooms.

- They do not support combustion, since they have a water base.

- Resistant to yellowing and UV rays. Therefore, the wood finish does not change its color.

- Simple instructions for use.

Tip: we recommend that prior to applying varnish on the surface, conduct a high-quality preparation, improving its adhesion.

Another plus of the product is that when using a sprayer inside the equipment, it practically does not remain, which indicates a high coefficient of its transfer.

Environmentally friendly colorless water-based varnish for Aqua wood for exterior and interior use

Disadvantages

The use of eco-friendly water-based varnishes has some negative aspects:

- high cost of the product,

- drying time can be a day,

- response to changes in humidity during the drying period,

- it is only necessary to store the product at a positive temperature, otherwise the water in it will freeze and it will lose its properties.

Application

- Clean the wooden surface from dirt. If necessary, sand it with sanding paper or a simple pumice stone.

Tip: we recommend using the wet grinding method when the tree should be moistened before processing, then treated and allowed to dry.

- Primer the surface to reduce varnish consumption. Wait until it is completely dry.

Do-it-yourself water-based varnish using a roller

- Prepare a brush, roller, spray or swab to apply polyurethane or acrylic varnish to the wood surface.

We recommend the following for:

- colorless varnish is best to use a roller or brush, the movement should be only along the fibers,

- dilution of the product use only clean water, do not use solvents or varnish,

- even distribution of the product on a wooden surface, it is better to apply several thin layers, and not be limited to one thick.

Environmentally friendly Synteko indoor varnish

Output

The use of colorless varnish for wood processing allows you to save the texture of the finishing material almost unchanged. In this case, you need to be prepared that some compounds may turn yellow after drying. The industry offers customers various types of colorless varnishes - oil, alkyd, polyurethane, acrylic, water-based and solvent-based (see also the article “Alkyd paint on wood - an overview of the main brands and marking features”).

Each of them has its own application technology, which is always prescribed on the packaging. The video in this article will provide an opportunity to find additional information on the above topic.

How to cover the floor, lining, stairs, OSB in a wooden house?

the surface is varnished, which ensures the safety of the material and its properties.

Those who neglect such treatment, after a few years, may find chips, cracks, abrasions and commonplace pollution on it.

What are the benefits of a wooden texture that has been processed?

- Prevention of mold and rot.

- Resistance to various mechanical damages.

- Sun protection.

- Increased fire resistance

- Aesthetics.

Often the lining during installation is processed by various special-purpose compounds: drying oil, antiseptic, and stain. The initial appearance of the material changes slightly. Coating the lining on top with varnish refreshes and ennobles it.

Choosing the Right Tool

How and with what to cover a tree?

Before starting work on applying varnish, it is first better to familiarize yourself with their varieties.

The following types are considered the most popular:

- water soluble

- alkyd,

- polyurethane

- acrylic.

Representatives of all these groups can be used for interior decorating: they do not emit harmful toxic fumes and are harmless to health. What are the features and operational characteristics of these tools?

Water soluble

Water-based varnishes are characterized by the absence of an unpleasant odor and sufficiently fast complete drying. They are completely non-toxic, so that the coloring of the lining in the room can be done without the use of protective equipment.

You don’t even need a respirator. Use similar compositions for processing a wooden surface exclusively indoors.

All water-based formulations have a polyurethane or acrylic base. They can have a different composition - two-component or one-component.

Acrylic

These varnishes help the wood perfectly preserve its unique natural texture. They will be an excellent choice for finishing the inner surface of the premises. In addition to improving the aesthetic qualities of the processed surface, they protect it from harmful effects, including from sunlight. The composition of acrylic varnishes may vary slightly, so you need to carefully study the instructions.

These varnishes help the wood perfectly preserve its unique natural texture. They will be an excellent choice for finishing the inner surface of the premises. In addition to improving the aesthetic qualities of the processed surface, they protect it from harmful effects, including from sunlight. The composition of acrylic varnishes may vary slightly, so you need to carefully study the instructions.

Following it, the compounds are diluted with ether, alcohol or water. The mixture dries almost instantly after application. Surfaces treated with acrylic-containing products do not apply to excess moisture, therefore, in the event of contamination, it is better to refrain from trying to wash them off with water. For the same reason, acrylic-based varnish is not very suitable for use, for example, in a kitchen, where humidity is usually high.

Alkyd

They have almost all the characteristics of the previous ones, but plus they are not yet afraid of high humidity, and even the moisture itself. Therefore, the surface treated by them can be washed safely.

They have almost all the characteristics of the previous ones, but plus they are not yet afraid of high humidity, and even the moisture itself. Therefore, the surface treated by them can be washed safely.

But it is not recommended to use abrasive substances and household chemicals.

The possibility of washing with water is very important, especially in the presence of children or pets.

Alkyd varnish coating is highly durable, protecting wood even from significant mechanical impacts: It prevents scratches, chips and other damage.

It is wonderfully used as a varnish for doors. The disadvantages of this drug are the unpleasant odor when used, as well as a sufficiently long time necessary for it to completely dry. It requires at least two days. But this drawback is not difficult to eliminate by adding a specially produced hardener to it.

Polyurethane

The advantages of this group of varnishes are difficult to overestimate.

They not only protect the material from aging and harmful effects, giving it a spectacular appearance.

They allow him to acquire completely unique qualities that are completely not characteristic of capricious natural material:

- high resistance to ultraviolet radiation,

- increased resistance to moisture,

- resistance to the action of aggressive agents such as alkali.

The remarkable characteristics of the drug determine its corresponding cost.

Nuances of using varnish

There are important features of the use of water-soluble varnishes, given which you can get a more aesthetic and high-quality result.

- Do not forget to varnish treatment before varnishing.

- Any type of varnish is best applied in at least two layers. So you can achieve maximum strength of the protective film on the material.

- When working, the varnish composition needs regular mixing. So its structure will be more uniform, it will be easier and more even to lay down.

The process of applying varnish

How to apply varnish correctly? Wood and lining should be well dried, only after that you can proceed to its decorative decoration. After lining the surfaces should pass at least five days. There are no particular difficulties in the application process. The procedure is not at all difficult to perform on your own. But it is advisable to use the recommendations of experienced professionals for this.

How to apply varnish correctly? Wood and lining should be well dried, only after that you can proceed to its decorative decoration. After lining the surfaces should pass at least five days. There are no particular difficulties in the application process. The procedure is not at all difficult to perform on your own. But it is advisable to use the recommendations of experienced professionals for this.

What you need to work:

- actually the varnish composition,

- capacity for him

- large and small brushes and rollers,

- fine sandpaper

- solvent, gloves, stepladder.

The surface is well cleaned, dust and dirt are removed. If there is an old coating, it must be removed. Old varnish is easily removed with soda. Places affected by fungus or mold are treated with a disinfecting and bleaching solution. The material needs high-quality grinding. To do this, use a special grinder or ordinary sandpaper.

When all defects are removed and the irregularities are smoothed out, a primer layer is applied to the surface, which fills the wood pores. After it dries, a special antiseptic composition is used, which helps to increase the life of the wood. This is the so-called covering layer.

After about a day, no less, you can proceed directly to the varnish coating of the house. It is better to use a brush made of natural bristles for this.

During use, individual hairs do not fall out of it, complicating the process and worsening the quality of work. The varnish should be mixed so that a homogeneous, uniform mass is obtained. Then it will lay down in a thin and even layer, and the coating will not have sloppy stains.

Requirements

Clear wood varnish should:

- form a durable coating and provide a sufficient degree of protection against environmental factors,

- emphasize the beauty of wood,

- be environmentally friendly, safe, free of toxins and used in different conditions, without harming children and adults,

- have a long service life without the cost of restoration during operation,

- Easy to apply and dry quickly.

Transparent varnishes can be:

- one-component

- two-component (with hardener),

- multicomponent (in addition to hardener, include solvents and other additives).

The scope is quite extensive. Colorless varnish can not only perform a decorative function, giving things a beautiful appearance with or without shine, but also protect them from scratches and significant damage, as well as changes associated with weather conditions or the microclimate in the house. Wooden toys, pencils, musical instruments, furniture, floors, walls and even yachts cover transparent varnish. In the interior of the houses, they paint wooden panels for walls or parquet boards for the floor, and are also used to cover the external facades of houses, baths and gazebos.

Depending on the basis, several types of varnishes are distinguished.

- Acrylic. The most popular view. It is diluted with water, has no smell and toxins in the composition, fire retardant, vapor permeable, easy to apply. Such a coating will be brittle, prone to abrasion. Acrylic-urethane varnish has improved properties.

- Alcohol (polish). Quick-drying varnish, available due to its relatively low cost. The resulting film is quite brittle, loses strength when heated, burns.

- Oil. Its density and strength depend on the ratio of resin to oil in its composition. Greasy varnishes, although they dry longer, but are more resistant.

- Smolyanoy. Its distinguishing feature is plasticity, which directly depends on the use of natural or artificially synthesized resins. Dries faster than oil varnish, but inferior in strength to it.

- Alkyd. Depending on the constituent components, it requires the addition of a thickener or hardener, accelerating its drying. Durable, withstands high humidity and temperature changes. Urethane brands last twice as long.

- Epoxy. Withstands heavy loads, does not scratch, does not wear. Service life depends on the application, but this figure is quite high. The object covered by it will be reliably protected.

- Polyester. Refers to multi-component varnishes. The coating does not deform when heated, water and chemicals.

- Nitrocellulose. It has average performance for all requirements, but dries well. The resulting film may become deformed if wetted.

- Polyurethane Drying time is measured not in days, but in weeks. The resulting layer is comparable in strength to the hardest minerals. It protects the surface in all weather conditions.

Most of these transparent varnishes, although they do not contain special pigments that give them color, after hardening acquire a yellowish tint. When applied to the natural color of wood, this can make it darker in tone.

Such changes in the direction of brightness are not critical, but they must be taken into account.

Primers for wood

This is essentially not a varnish, but a composition that is applied to a tree in order to strengthen its adhesion to the finish coating, varnish. The primer coating is used when you need to get a more even color, or save on the finish coating, because the first coat takes the most of the composition (no matter how the varnish is a surface coating, a small part is absorbed by the top layer of the tree).

When choosing a primer varnish, you need to be especially careful that it fits the topcoat.

Oil, or oil-resin varnishes for wood

Oil (also called oil-resin) varnishes for wood used to be used everywhere, but today their popularity has fallen sharply. As the name implies, such varnishes made from oils and resins , in different proportions. Previously, such varnishes were made on the basis of natural products and therefore were very expensive, but with the advent of artificial components, their cost decreased markedly.

Depending on the amount of oil in such a varnish, they can be conditionally divided into three types:

- greasy - 65% -85% of the oil in the composition,

- medium - 55% -65% of the oil in the composition,

- skinny - 35% -55% of the oil in the composition.

As expected, the more oil and less resin in the varnish, the better it protects the tree, but the longer it dries. The drying time of such varnish is from 24 to 72 hours. Well, of course, the longer the varnish dries, the better it penetrates the wood. This varnish is too thick, and therefore it is often diluted. Wood penetration is high.

Alkyd-carbamide varnishes for wood

This is a two-component varnish, in addition to alkyd resins, the composition of the varnish includes amino formaldehyde resins. Drying of this varnish is possible only with the introduction of a special hardener. After mixing the hardener, the varnish hardens from several hours to a couple of days, it all depends on the amount of hardener added.

Durable, and most importantly waterproof, varnish that has a strong sheen. It is used in sone for covering, parquet and flooring, but it can also be used for other wooden products.

Water-based Acrylic Wood Varnish

This type of varnish can be called the safest, therefore it is most often used for internal work, with those types of products with which we most often come in contact. Acrylic varnish is diluted with water, almost odorless, non-toxic, lays well on a tree, lets steam through, can even withstand fire to some extent. But this varnish has its drawbacks, they dry for a long time, the final drying period can take up to two weeks, they are not very durable, they do not provide high-quality protection against moisture. Special additives will help improve the mechanical resistance of acrylic varnish.

Nitrocellulose (ethercellulose) varnishes for wood

This type of varnish consists of: cellulose nitrate, an organic solvent, resins and a plasticizer. Is very popular varnish for interior work , for processing furniture, walls, musical instruments, but is not used to protect the floor. The varnish dries very quickly, the drying time is only 20 minutes and up to a couple of hours. It is very well polished, and as a result a very hard and smooth coating with a high decorative effect is obtained. Of the minuses: an unpleasant odor (remember about the solvent), which completely disappears after drying, as well as "dislike" for the sun and moisture.

Epoxy varnishes for wood

This is a two-component varnish, the basis of which is epoxy resin and hardener. After mixing the components, the varnish is applied to the product and begins to harden. High hardness, resistance to shock and moisture. Suitable for both indoor and outdoor use. Another plus is the quick drying time, about 12 hours.

Polyester varnishes for wood

This is a multi-component varnish for wood based on polyester resins. The varnish is very durable, resistant to chemistry, heat, water. This varnish is applied with a special gun and requires a lot of experience in work. After drying, a shiny and transparent crust is obtained. It is mainly applied to musical instruments, sometimes to furniture.

Alcohol varnishes (varnishes) for wood

These varnishes are made on the basis of ethyl alcohol and the resins dissolved in it. Alcohol disappears too quickly and therefore the drying time of the varnish is from 20 minutes to one hour. Fast drying clearly does not contribute to high-quality absorption, and therefore the varnish provides a fairly mediocre protection. The only plus is a small price. Usually used to cover musical instruments (cheap), rarely used in carpentry